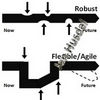

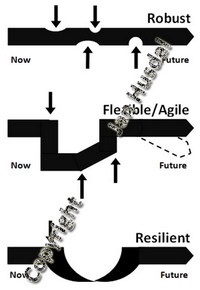

Several “buzzwords” have been linked to supply chain risk management (SCRM) in various ways: robustness, flexibility, agility and resilience. These concepts are often confused, and thus, warrant further explanation. They are distinctively different, and which strategy that works best would depend not only on the supply chain in question as a whole, but also which part of the supply chain that may be vulnerable. That is why it is useful to look at what sets one apart from the other.

Several “buzzwords” have been linked to supply chain risk management (SCRM) in various ways: robustness, flexibility, agility and resilience. These concepts are often confused, and thus, warrant further explanation. They are distinctively different, and which strategy that works best would depend not only on the supply chain in question as a whole, but also which part of the supply chain that may be vulnerable. That is why it is useful to look at what sets one apart from the other.

Note:

This post is based on my previous work in

husdal.com: Flexibility and Robustness (2004)

husdal.com: Robustness, flexibility and resilience (2008)

The framework in this post has been further refined in later posts:

husdal.com: Robust, Flexible, Agile, Resilient. What does it mean? (2015)

Various approaches

Over the years, many definitions have popped up throughout the literature and some of my thoughts have already been posted in my previous post on robustness, resilience and flexibility. Here is an updated version, with references to the supporting literature. Mind you, this is not meant as an exhaustive list, it is just a selection of articles that I have found useful:

Goranson (1992) differentiates between agility and flexibility. Flexibility is scheduled or planned adaption to unforeseen yet expected external circumstances. Agility is unplanned and unscheduled adaption to unforeseen and unexpected external circumstances.

Rice & Canatio (2003) focus on security and resilience by upholding flexibility and redundancy as two methods with the greatest potential to create resilience. Redundancy is capacity that may or may not be used; it is this additional capacity that would be used to replace the capacity loss caused by a disruption. Flexibility, on the other hand, entails redeploying previously committed capacity.

Lee (2004) uses the term “Triple-A” supply chain (agility, adaptability and alignment). Agility means to respond quickly to changes (and disruptions) in supply and demand, adaptability means to adjust to shifting markets and alignment implies an equitable sharing of costs, gains, risks, knowledge and information across the whole supply chain.

Christopher & Peck (2004) contend that resilience implies agility, and define supply chain agility as the ability to quickly respond to unpredictable changes in demand and supply, slightly akin to Goranson’s definition. An agile and responsive supply chain, they argue, requires agile partners upstream and downstream of the focal firm.

Lummus, Duclos & Vokurka (2003) and Duclos, Vokurka & Lummus (2004) see flexibility as a cross-enterprise undertaking composed of 6 components: 1) operations – the ability configure assets and operations according to customer trends, 2) market – the ability to customize design and build close relationship with customers, 3) logistics – the ability to receive and deliver according to locational changes in supply and demand, 4) supply – the ability to reconfigure the supply chain, 5) organization – the ability to align labor force skills with customer or demand requirements and 6) information systems – the ability information systems architectures and systems with changing information needs in response to changes elsewhere in the organization.

Sheffi (2005) sees flexibility as a way to achieve resilience, stating that instead of relying solely on supply chain redundancy, a well-managed firm should develop resilience, by building flexibility that can be used to ‘bounce back’ from disruptions. To me, that would rather be agility (in line with Goranson’s definition) than flexibility.

Tomlin (2006) differentiates between contingent and mitigative actions. Flexibility can here be seen as a contingency action, that is: actions taken in the event of a disruption. Redundancy can be seen as a mitigation action, that is: actions taken in advance of a disruption, hence incurring a cost regardless of disruption.

McManus et al. (2007) view resilience as depending on 1) keystone vulnerabilities, criticality and preparedness, 2) situation awareness, stemming from an assessment of the keystone vulnerabilities, and 3) adaptive capacity, which is nothing other than flexibility and agility. Resilience, in essence, is the ability to survive disruptive changes despite severe impact.

Asbjørnslett (2008) sees flexibility or agility as the inherent capability to modify a current direction to accommodate and successfully adapt to changes in the environment, whereas robustness refers to the ability to endure such changes without adapting. Resilience is the ability to survive despite withstanding a severe and enduring impact.

In summary

Flexibility or agility, robustness and resilience are different sides of the same coin, yet at the same time distinctively different animalsThe difference between robustness, flexibility, agility and resilience is illustrated in the figure below, taken from Husdal (2009). Note that there is a distinct notion of different severity in each of these definitions.

The ability to survive (resilience) is likely to be more important in a business setting than the ability to quickly regain stability (robustness) or the ability to change course (flexibility or agility). Supply chain risk management must include all.

Reference

Asbjørnslett, B. (2008). Assessing the Vulnerability of Supply Chains. In Zsidisin, G. A., & Ritchie, B. (Eds.) Supply Chain Risk: A Handbook of Assessment, Management and Performance. New York, NY: Springer.

Christopher, M., & Peck, H. (2004). Building the Resilient Supply Chain The International Journal of Logistics Management, 15 (2), 1-14 DOI: 10.1108/09574090410700275

Duclos, L., Vokurka, R., & Lummus, R. (2003). A conceptual model of supply chain flexibility Industrial Management & Data Systems, 103 (6), 446-456 DOI: 10.1108/02635570310480015

Goranson, T. (1999). The Agile Virtual Enterprise. Westport, CT: Quorum Books

Husdal, J. (2009). Does location matter? Supply chain disruptions in sparse transportation networks. Paper presented at the TRB Annual Meeting, Washington DC.

Lee, H. L. (2003). The Triple-A Supply Chain Harvard Business Review, 82 (10), 102-112

Lummus, R. R., Duclos, L. K., & Vokurka, R. J. (2003). Supply Chain Flexibility: Building a New Model Global Journal of Flexible Systems Management, 4 (4), 1-13

Mc Manus, S., Seville, E., Brunsdon, D., & Vargo, J. (2007). Resilience Management: A Framework for Assessing and Improving the Resilience of Organisations (Report No. 2007/01). Christchurch, New Zealand: Resilient Organisations.

Rice, J. B., & Caniato, F. (2003). Building a secure and resilient supply network. Supply Chain Managment Review, 7(5), 22-30.

Sheffi, Y. (2005). The Resilient Enterprise – Overcoming Vulnerability for Competitive Advantage. Cambridge, MA: MIT Press.

Tomlin, B. (2006). On the Value of Mitigation and Contingency Strategies for Managing Supply Chain Disruption Risks Management Science, 52 (5), 639-657

Related

- husdal.com – Robustness and flexibility as options to reduce uncertainty (2004)

- husdal.com – Robustness, Resilience and Flexibility in the supply chain (2008)

- husdal.com – Robust, Flexible, Agile, Resilient. What does it mean? (2015)