A new field has emerged with the field of supply chain mangement. It’s called supply chain risk. What is supply chain risk? Today I will take a closer look at the chapter titled “Managing risk in the supply chain” in Logistics & Supply Chain Management

A new field has emerged with the field of supply chain mangement. It’s called supply chain risk. What is supply chain risk? Today I will take a closer look at the chapter titled “Managing risk in the supply chain” in Logistics & Supply Chain Management by Christopher Martin, as reviewed in my previous post. A supply chain is often imagined as a streamlined flow from a supplier to a company, from where it flows effortlessly on to a customer. So much for the theory. In reality, the emergence of various supply chain management strategies and practices contribute to considerable chaos within these supply chains, and iIt is not surprising then that supply chains have become vulnerable, where even minor disruptions may result in chain-wide impacts across the whole supply chain. Along with supply chain risk, supply chain vulnerability is also and new and emerging field in the realm of supply chain management.

Reasons for increased supply chain vulnerability

- The trend towards just-in-time and lean practices have led to a focus on efficiency rather than effectiveness.

- The trend towards reducing costs (at almost any cost) has led to a globalization of supply chains, more complex and hence more vulnerable.

- The trend towards economies of scale has led to centralized distribution and manufacturing, which has lowered costs but at the same time also made the supply chain less flexible.

- The trend towards outsourcing non-core business activities in order to gain market competitiveness has led to loss of control of the supply chain when it may be most needed.

- The trend towards consolidation of suppliers, not necessarily brought on by the customer company itself, but by incidental mergers and acquisitions has led to an increased risk of supply failure.

Supply chain risk management is closely linked to “business continuity” planning, since the biggest risk to business continuity may in fact be in the wider network (or supply chain) the individual business is just a part of. This means that one’s own continuity may be very much dependent on someone else’s continuity, and mapping an individual company’s risk profile involves identifying risk sources across the network.

Sources of supply chain risk

- Supply risk – disruptions in supply

- Demand risk – volatile demand and the bullwhip effect

- Process risk – operational constraints and limitations

- Control risk – decision rules hampering own production

- Environmental risk – external forces, natural hazards, politics

Suply chain risk profile

It is important for any business to understand that its own risk profile is directly and indirectly impacted by the strategic decisions that are made. A business’ vulnerability should always be examined in relation to the 5 sources of risk as described above.

Mapping the risk profile is a six step process that involves

- Prioritize earnings drivers

- Identify critical infrastructure that affect the earnings drivers

- Locate vulnerabilities in the critical infrastructure

- Model scenarios for the vulnerabilities

- Develop responses to the scenarios

- Monitor and detect potential disruptions as soon as possible

Managing supply chain risk

- Understand the supply chain

– view it from end to end, from supplier to end customer. - Improve the supply chain

– can you simplify and reduce complexity and variability? - Identify critical paths

– what are the bottlenecks and key nodes/links? - Manage the critical paths

– make contingency plans. - Improve network visibility

– don’t be afraid to share information. - Establish a supply chain continuity team

– make it cross-functional - Work with suppliers and customers

– are your suppliers and customers aware of their own vulnerabilities?

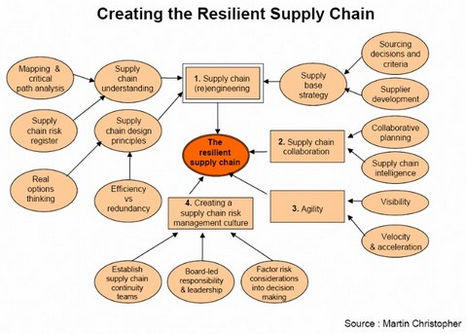

Achieving supply chain resilience

Supply chain resilience requires a recognition that all strategic decisions have an impact on the supply chain and the supply chain risk profile. Hence, it may be necessary to re-engineer the supply chain. How this process works can be seen in the figure below.

In conclusion, the chapter on supply chain risk in in Logistics & Supply Chain Management by Christopher Martin provides a comprehensive and thorough perspective for anyone interested in the subject matter. As I said before, this chapter alone makes the book worth reading.

Reference:

Christopher, M. (2005) Managing risk in the supply chain. In: Logistics and Supply Chain Management, 3rd ed, Prentice Hall, pp. 233-258

Related posts

- husdal.com: Book Review – Logistics and Supply Chain Management

- husdal.com: Supply Chain Risk – the forgotten subject?