How are companies located in sparse transport networks affected by supply chain disruptions? Here is a copy of the paper I presented at TRB2009, the Transportation Research Board 88th Annual Meeting, in Washington, DC, 11-15 January 2009. The paper was presented in a poster session and included as a full paper in the conference proceedings. For your convenience, both the paper and the poster are included below.

How are companies located in sparse transport networks affected by supply chain disruptions? Here is a copy of the paper I presented at TRB2009, the Transportation Research Board 88th Annual Meeting, in Washington, DC, 11-15 January 2009. The paper was presented in a poster session and included as a full paper in the conference proceedings. For your convenience, both the paper and the poster are included below.

Reference

Husdal, J. (2009). Does location matter? Supply chain disruptions in sparse transportation networks. Paper presented at the TRB Annual Meeting, washington DC, 11 January 2009.

Abstract

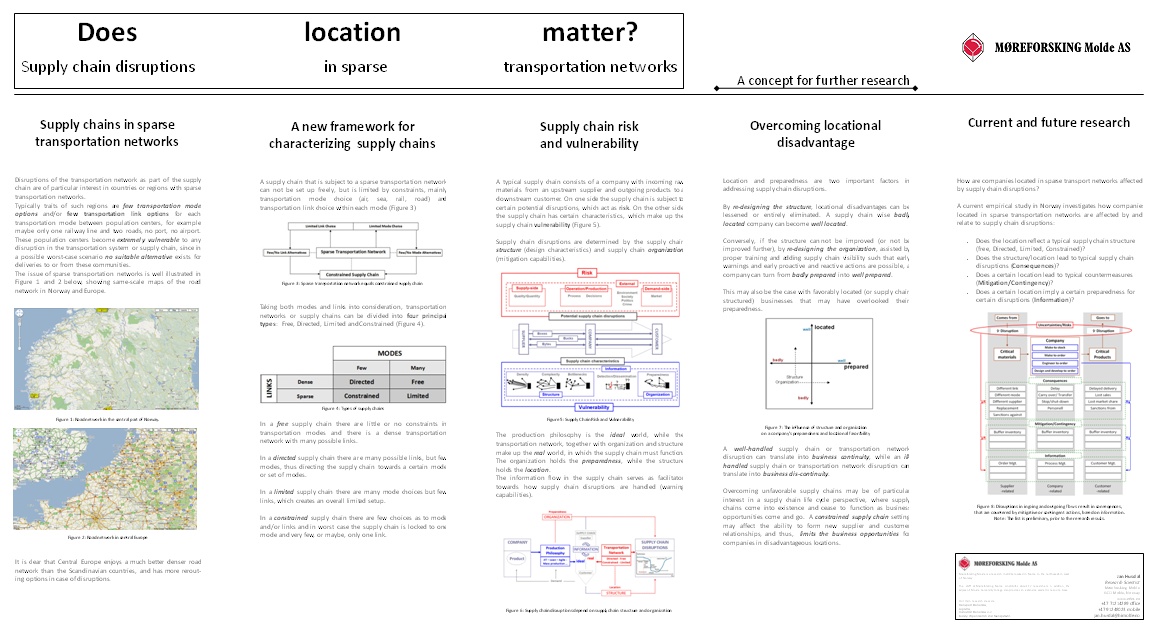

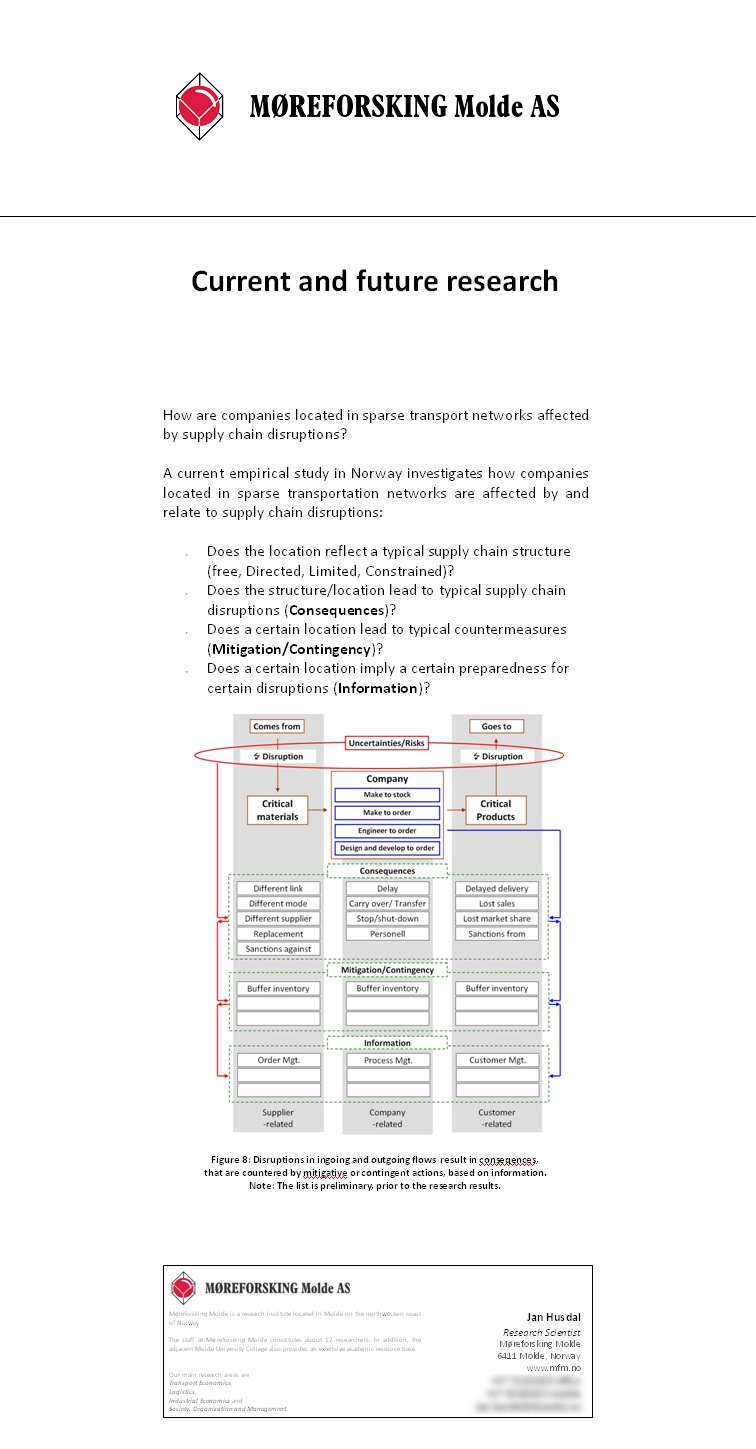

This paper serves as a conceptual gateway for further research into supply chain disruptions in sparse transportation networks.

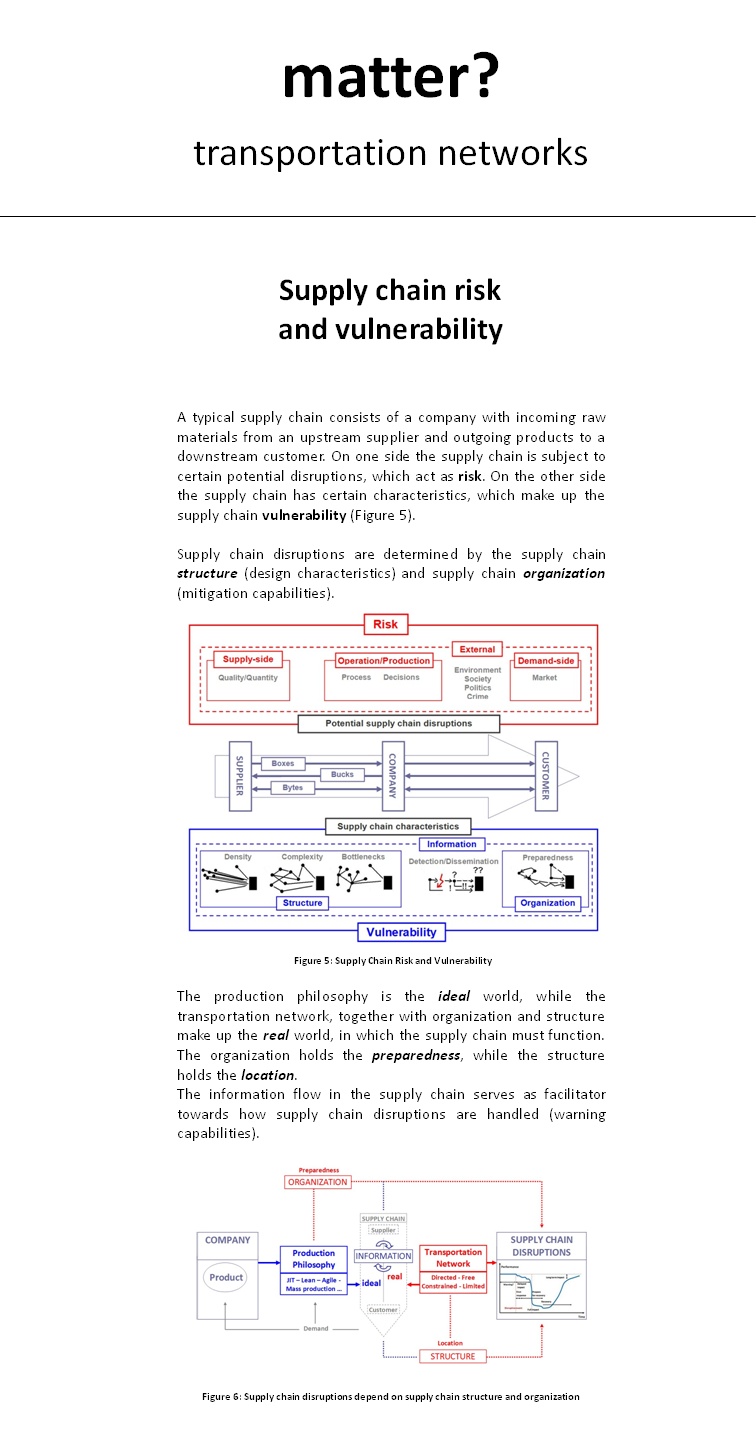

Disruptions of the supply chain are of particular interest in countries or regions with sparse transportation networks. Here, the supply chain can not be structured freely, but is limited by constraints, and with only a few transportation modes and links available between communities, they become extremely vulnerable, since in a worst-case scenario no suitable alternative exists for deliveries to or from communities. Thus, the structure or design of the supply chain, along with the organization and preparedness become important factors in determining if a company has a favorable or an unfavorable location.

The question then arises, are businesses located in regions with sparse transportation networks more prone to supply chain disruptions than businesses located in more favorable locations? Does a sparse transportation network constrain the supply chain setup, such that it is more vulnerable and more likely to be disrupted?

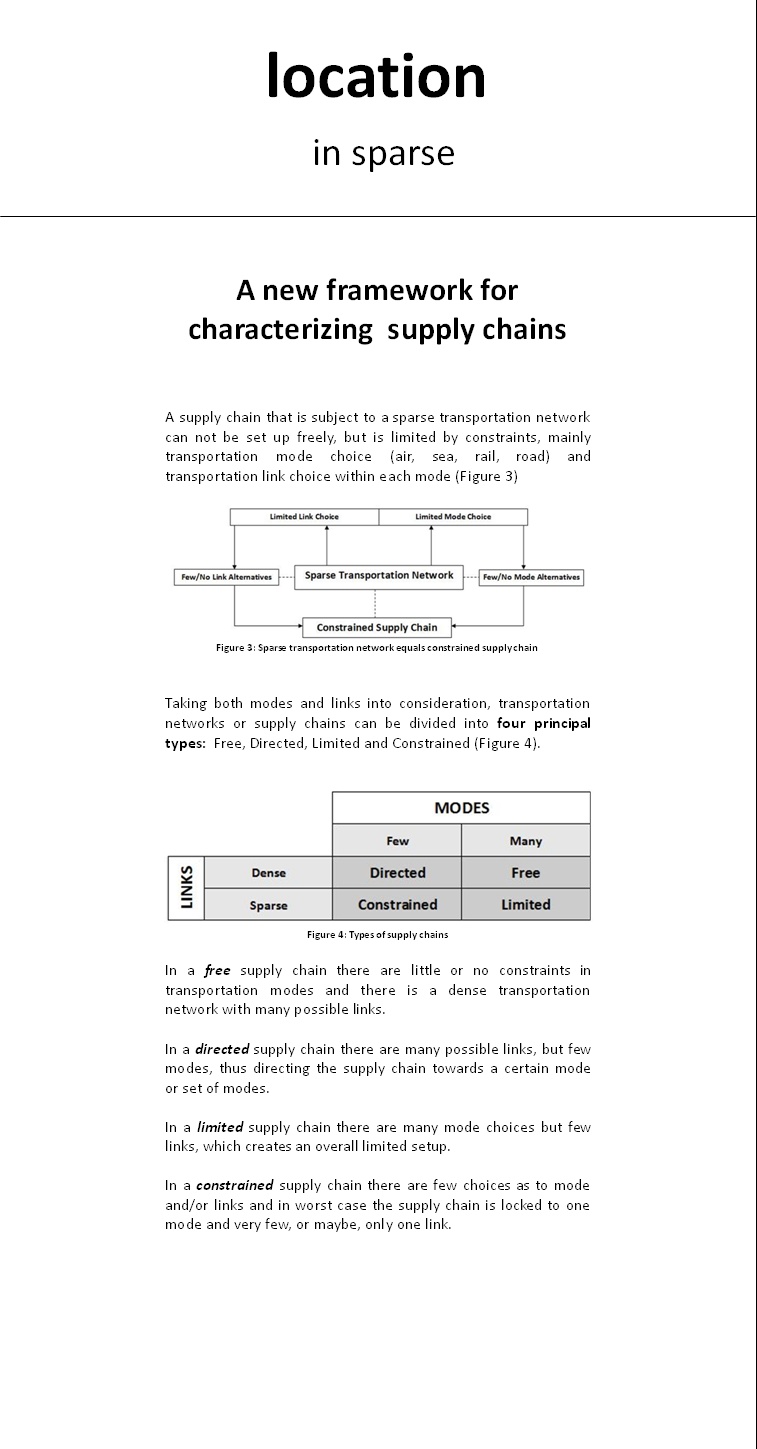

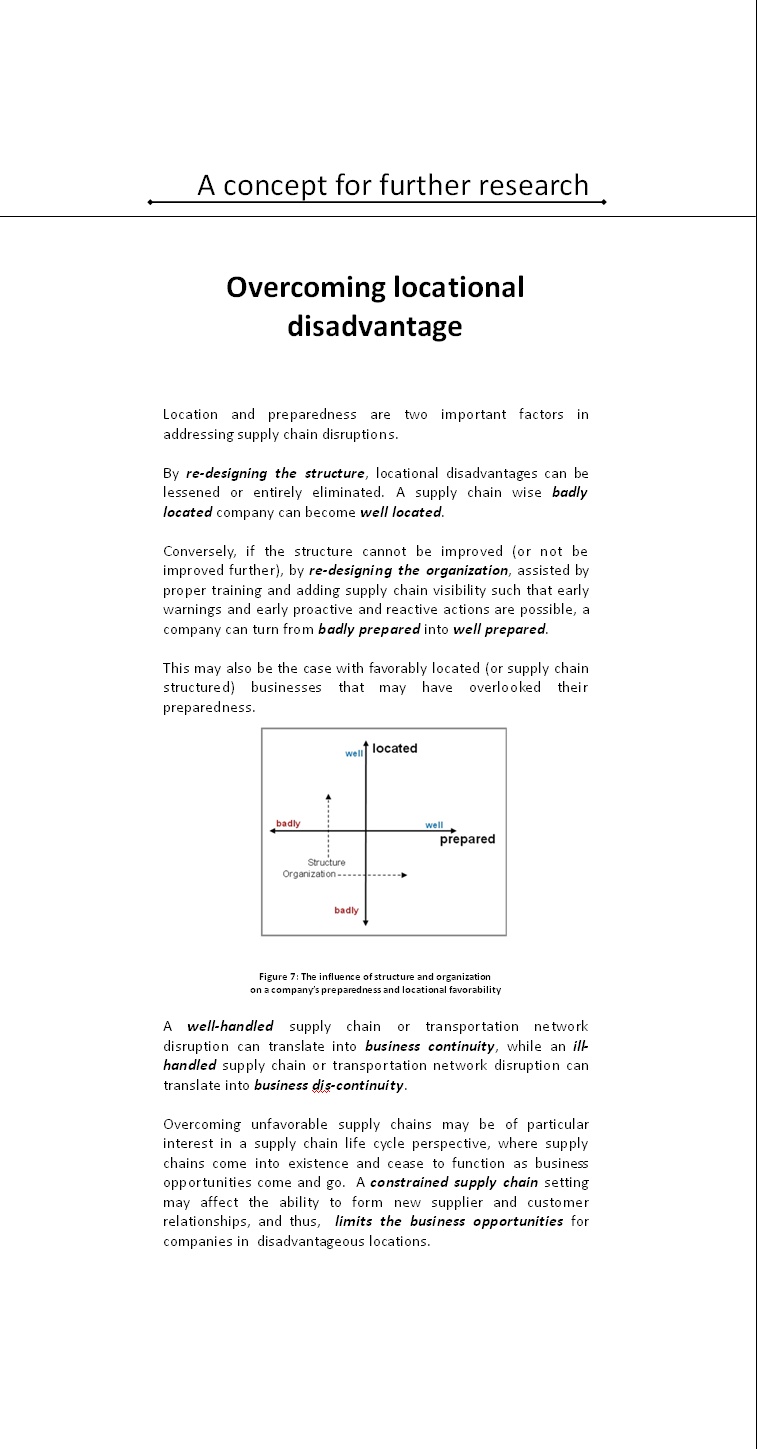

The paper develops a new framework for the categorization of supply chains, based on the number of links and modes available in the transportation network, where sparse transportation networks can be categorized as constrained supply chains with an unfavorable supply chain setup. Within the constrained supply chain framework, a company can address its locational disadvantage by either redesigning the supply chain towards a better structure, in order to gain better location, or by redesigning the supply chain towards a better organization, in order to gain better preparedness.

Poster

|

|

|

|

|

|

Full paper

Update

This paper preceded the research that was to come. An updated paper based on the actual research that was done, can be found in this post: Bad Locations – Bad Logistics? How Horwegian freight carriers handle transportation disruptions

Related

- husdal.com: Location, location, location

- husdal.com: Does location matter?

- husdal.com: TRB2009 – are you going there?

- husdal.com: Are roads more important than computers?