I’ve said so before, sometimes new articles are found in new and unlikely places. The other day I was proofreading the paper of a colleague and something caught my attention in her reference list. A brand new article, just out: Managing disruptions in supply chains: A case study of a retail supply chain by Adegoke Oke and Mohan Gopalakrishnan. Now, here was a chance to learn something new…so I thought, and so I did. However, I’m not sure I follow the authors in their risk categorization: supply, demand and “miscellanous” risk? What is this “miscellanous” risk?

I’ve said so before, sometimes new articles are found in new and unlikely places. The other day I was proofreading the paper of a colleague and something caught my attention in her reference list. A brand new article, just out: Managing disruptions in supply chains: A case study of a retail supply chain by Adegoke Oke and Mohan Gopalakrishnan. Now, here was a chance to learn something new…so I thought, and so I did. However, I’m not sure I follow the authors in their risk categorization: supply, demand and “miscellanous” risk? What is this “miscellanous” risk?

No consensus

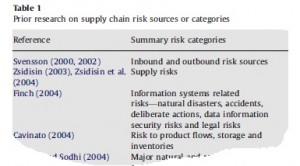

The authors start out by lamenting that supply chain risk research has resulted in many frameworks and concepts of risk categories and risk mitigation measures, but there is yet to be a consensus on which framework that best captures different types of supply chain risks.

Click image for larger version

Click image for larger version

Frankly speaking, I don’t think there ever will be consensus, simply because supply chains are so varied in nature and it will be impossible to design a framework that encompasses all variations in a generic structure. The authors also point out that much research has been spent on low-impact high-likelihood risks, and very little has been done on high-impact low-likelihood risks. Really? Paul Kleindorfer has done a lot.

Research questions

The authors ask and answer the following questions:

- What are the different types of risks or potential risks in a retail supply chain?

- What are the mitigation strategies required to manage these risks? And which of these are generic and which are specific to a particular type of risk?

While the questions are geared towards the retail industry, the resulting framework has a general application.

Risk categorization in supply chains

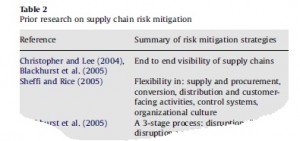

In their review of some 20 papers (some well-known and not so well known to me and some unknown), Oke and Gopalakrishnan remark that risks fall into either low-impact high-likelihood inherent and frequent risk or low-likelihood high-impact disruption and infrequent risk. I find it interesting that they see “disruption” as a high-impact risk.

Click image for larger version

Click image for larger version

(Sidenote: In a book chapter I will review later, the risks are classified as deviation, disruption and disaster, in that order, making disruption a somewhat lesser risk than disaster.) Oke and Gopalakrishnan further argue that the simple classification of supply chain risks as high-likelihood low-impact and low-likelihood high-impact is not only highly relevant for classifying supply chain risks, but it also represents the key to identifying relevant mitigation strategies.

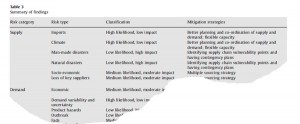

Three types of risk

In defining types of risks, the authors follow to traditional separation of supply-related and demand-related risk, but they also introduce a third type which they call miscellanous risk. What is miscellaneous risk and why do they invent a “new” type of risk? What they list as examples of miscellaneous risk I believe is what many researchers before them have labeled as external risk or operational risk, e.g. safety regulations imposed by government agencies, increased cost of raw materials, increased logistics costs because of increased gas prices and actions by pressure groups wishing to enforce stricter ethical business practices. Yes, they are miscellaneous, but they fit very well within the established types of risks that many researchers have used before them, e.g. the book chapter on supply chain risk in Christopher (2005).

Risk categories and mitigation strategies

In conclusion the authors come up with four propositions:

- Most supply chain risks fall are either one of these two: low-impact high-likelihood or high-impact low-likelihood.

- High-likelihood low-impact risks can be mitigated using generic strategies aimed at planning and coordination of supply and demand.

- Low-likelihood high-impact risks must me mitigated using specific strategies aimed at the particular risk.

- Miscellaneous risks (better: operational risks) can be mitigated using specific strategies aimed at efficiency gains and cost reduction.

Finally, the authors set up a table where they classify the typical retail risks they earlier had identified in each category and suggest their appropriate mitigation strategies.

Click image for larger version

Click image for larger version

Conclusion

What I like about this paper is the clear structure, the concise literature review, (although I would have liked to see a few more papers, but I can’t complain, I found a couple of new ones), four defined propositions and a practical retail-oriented application of their theoretical framework. What I don’t like is the invention of a “miscellaneous” risk category, whatever that is. Was it in lack of a better category? It is as if there’s supply, there’s demand, and then there’s everything else. That said, it is an excellent paper, nonetheless . And if I replace miscellaneous with operational this is an almost perfect paper.

Reference

Oke, A., & Gopalakrishnan, M. (2009). Managing disruptions in supply chains: A case study of a retail supply chain International Journal of Production Economics, 118 (1), 168-174 DOI: 10.1016/j.ijpe.2008.08.045

Author Links

- aimresearch.org: Adegoke Oke

- asu.edu: Mohan Gopalakrishnan

Related

- husdal.com: What’s so special about Paul Kleindorfer?