This week’s focus are risks in the maritime supply chain, and today’s article introduces a new methodology for integrating risk management procedures into planning and design of maritime transportation networks. Risk Management in Maritime Transportation Networks, by by Christian Nedeß, Axel Friedewald, Lars Wagner, and Lutz Neumann is a book chapter in Managing Risks in Supply Chains: How to Build Reliable Collaboration in Logistics, edited by Wolfgang Kersten and Thorsten Blecker. This article has both captured my imagination and clarified my understanding of risks in maritime transportation networks, much of it due to an excellent use of clear-cut graphics, showing that authors not only know their subject well, they also know how to convey it well.

This week’s focus are risks in the maritime supply chain, and today’s article introduces a new methodology for integrating risk management procedures into planning and design of maritime transportation networks. Risk Management in Maritime Transportation Networks, by by Christian Nedeß, Axel Friedewald, Lars Wagner, and Lutz Neumann is a book chapter in Managing Risks in Supply Chains: How to Build Reliable Collaboration in Logistics, edited by Wolfgang Kersten and Thorsten Blecker. This article has both captured my imagination and clarified my understanding of risks in maritime transportation networks, much of it due to an excellent use of clear-cut graphics, showing that authors not only know their subject well, they also know how to convey it well.

The importance of maritime transportation networks

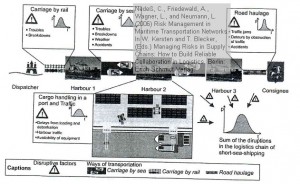

As already mentioned in the two preceding posts, merchant shipping and port services play a key role in worldwide supply chain and logistics activities, and many industries are reliant on a well-coordinated, time and cost-efficient performance of maritime transport, storage and distribution processes. However, some current trends run against this:

- Increasingly larger vessels

- Higher traffic density

- Port bottlenecks

- Moorings

- Interim storage

- Transportation to and from the port and hinterland

In order to analyze maritime transportation networks and the influence of disturbances on the transportation processes, the Institute of Production Management and Technology at the Hamburg University of Technology developed a modular logistics simulation tool, which I will briefly touch upon below.

Step by step

The best way to review the paper is to show the excellent illustrations and figures, and I hope the authors will forgive me for so publishing their work without asking, but I’ve “watermarked” the figures so they are practically useless, just to be on the safe side.

The two-dimensional view of the risk model

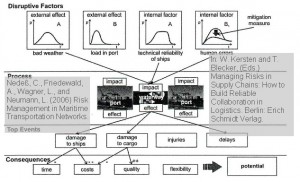

The authors classify risk in tow categories: Strategic risk, focusing on the long term view, and how to reduce the probability and/or consequence of adverse events, and operational risk, focusing on the transportation processes in a short-term perspective, looking at disruptive factors, processes, events and consequences:

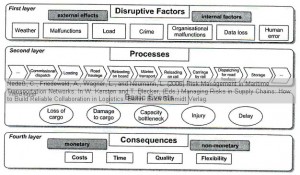

The layer model for maritime transportation risk management

The layered operational risk model is used to identify, evaluate and mitigate risks:

The Disruptive Factors layer defines the events which initiate the cause-effect. The Processes layer describes the processes in the examined system. The Events layer are the most likely occurring events. The Consequences layer contains monetary and non-monetary quantifiers.

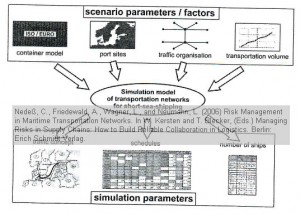

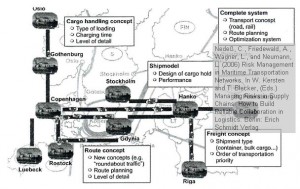

Simulation Model for short-sea-shipping

An important step in risk management is the estimation of risk occurrence probability and risk probability. This requires a a simulation model for evaluating the logistics processes that are exposed to the risks.

Here the Baltic sea is used as an example.

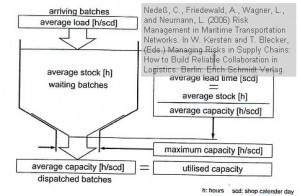

Basic risk modelling for simulation

The concept behind the basic model above is derived from a “Trichtermodell” simulating a bottleneck that funnels the incoming flow into an outflow.

The outflow then represents the port’s capacity or the result of a supply chain disruption.

Risk modelling in the maritime logistics simulation

These “funnels” are then inserted into the simulation model, along with the probabilities of their occurrence.

Shipment volumes are (here) based on forecasts.

Risk mitigation with effect analysis

The operational risk model then generates an outcome based on the events, and as already mentioned above, has a four-layer structure:

The first layer sums up all the disruptive factors. The second layer includes the information about the processes. The third layer represents the risk characteristics, grouped into top events. The fourth layer includes the evaluation criteria, as they are related to the supply chain objectives, e.g. cost, time, quality, and flexibility.

Logistics simulation model for short-sea-shipping

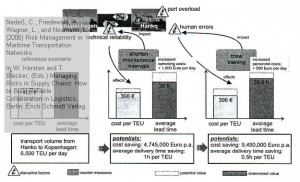

The paper includes a case example, short-sea-shipping in the Baltic Sea. Here, three disruptive factors are said to lead to capacity bottlenecks on the main waterway between Hanko and Copenhagen: Overload of port capacities, Technical (un)reliability of the ships, Human errors due to an inexperienced crew.

The second factor can be mitigated by shortening maintenance intervals, the third by measures for training crews. This can be quantified in time and money, so can the effects of capacity constraints in ports.

Example: Port capacity bottleneck

The model outputs the results of the reference scenario without mitigation and with mitigation,

showing clearly how the measures lead to less costs and less lead time.

Conclusion

This paper shows how dynamic logistics simulation can be used to assess risks and to evaluate the effect of mitigation measures, including impacts on time and costs. And the figures…simply brilliant! Say no more…

Reference

Nedeß, C., Friedewald, A., Wagner, L., and Neumann, L. (2006) Risk Management in Maritime Transportation Networks. In W. Kersten and T. Blecker, (Eds.) Managing Risks in Supply Chains: How to Build Reliable Collaboration in Logistics. Berlin: Erich Schmidt Verlag.

Author Links

- tu-harburg.de: Axel Friedewald

- tuhh.de: Christian Nedess

- linkedin.com: Lars Wagner

- unknown: Lutz Neumann

Related

- husdal.com: Risk and vulnerability in maritime supply chains

- husdal.com: Security in maritime supply chains