Humanitarian operations rely heavily on logistics in uncertain, risky, and urgent contexts, making them a very different field of application for supply chain management principles than that of traditional businesses. Decentralization, pre-positioning and pooling of relief items are key success factors for dramatic improvements in humanitarian operations performance in disaster response and recovery. So say Aline Gatignon, Luk N van Wassenhove and Aurelie Charles in their newest article, The Yogyakarta earthquake: Humanitarian relief through IFRC’s decentralized supply chain. I believe they are right.

Humanitarian operations rely heavily on logistics in uncertain, risky, and urgent contexts, making them a very different field of application for supply chain management principles than that of traditional businesses. Decentralization, pre-positioning and pooling of relief items are key success factors for dramatic improvements in humanitarian operations performance in disaster response and recovery. So say Aline Gatignon, Luk N van Wassenhove and Aurelie Charles in their newest article, The Yogyakarta earthquake: Humanitarian relief through IFRC’s decentralized supply chain. I believe they are right.

Ten years in the making

Ten years of responding to major disasters led the International Federation of Red Cross and Red Crescent Societies (IFRC) to design and implement decentralized supply chains for emergency response, through the establishment of three advanced Regional Logistics Units (RLUs) for spearheading relief operations. The article by Gatignon et al. (2010) reports on the lessons learned and experiences gained from this process.

When I was there

Interestingly, at the time of the Yogyakarta earthquake I was actually in Jakarta, some 400 kilometres away, on holiday, and when watching the news, the city looked utterly devastated. But was it? When I later visited Yogyakarta in 2009 there was little that reminded me of a city that supposedly lay in ruins 3 years earlier. There was little evidence of the substantial damage that had struck the city in 2006. It was almost as if the earthquake never happened.

That said, I wasn’t sure I was gong to survive upon landing at Yogayakarta – I’ve never in my life experienced a runway more bumpy than this one. At first I thought it to be a lack of piloting skills, but I realized the runway was indeed a really buckling piece of airstrip. Besides that, the only visible signs were some reconstruction work at the Prambanan temple and some minor damages at Borobudur. Alright, for the record, there were signs throughout the city, but you had to look close to actually see them.

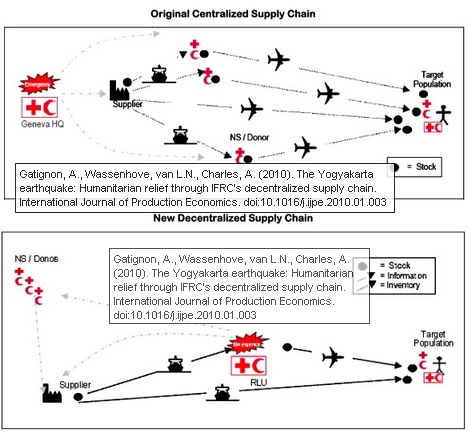

The decentralized supply chain

In the IFRC’s traditional centralized supply chain, relief items were typically transported in large batches through transcontinental flights. This is not only expensive, it also leads to logistical bottlenecks in receiving and storing the goods at local airports. or other nearby warehouses. The new decentralized supply chain with its prepositioned stocks and supplies allows for a quicker regional operation by air during the emergency phase. In this way, a faster response is possible during the crucial ramp-up phase of operations, as seen in Beresford and Pettit (2009).

The IFRC selected three locations for RLUs on the basis of their strategic positioning in terms of the IFRC’s global supply chain and operations:

- Dubai was chosen to cover Europe, the Middle East, and Africa,

- Kuala Lumpur was chosen to cover Asia and Australia,

- Panama was chosen to cover America

The Yogyakarta relief operations demonstrated that the IFRC’s decentralized supply chain works:

- Faster service, fully operational in three days.

- Better service to the disaster victims over a longer period of time.

- Much cheaper than previous interventions.

One reason why it worked so well is because the RLU is closer to the field of operations than headquarters in Geneva, Switzerlandand thus able to communicate more easily with donors in the same time zone and limit the number of unsolicited donations by advising donors as to which needs were still unmet.

A prestigeous award

It should be mentioned that the IFRC received the ‘European Supply Chain Excellence Award’ in 2006, winning recognition from external analysts and industry leaders within supply chain management.

For scale, responsiveness and performance, (the IFRC) are outstanding: all the more so when you realize that they exist to operate in precisely the places where normal supply chains have broken down; that they have only moral rather than legal charges over their sources of supply and funding; and that despite being a global brand with relatively little direct control over its local operations, it has successfully transformed its supply chain to meet even better the demands that the world places on it.

I find it quite amazing that an organization that is not originally designed to be a professional logistics operator has won such an award.

Faster, cheaper, better

As the Yogyakarta operation demonstrated, the successful implementation of the IFRC’s new model rested on a certain number of supply chain principles, which in combination created a better, faster, cheaper supply chain:

- Standardized items and processes (bucks and boxes)

- Traceability through adapted information systems (bytes)

- People skills (the three I’s)

What the IFRC did was to adopt Lee’s three A’s of supply chain management: agility, adaptability and alignment, where he latter element was only made possible by respecting the three I’s of supply chain management: identity, information processes, and incentive systems.

Conclusion

While the decentralized supply chain is a big step forward, fully implementing the decentralized supply chain remains a huge challenge, as the establishing of the RLUs shifted the IFRC’s power center towards the local level and away from headquarters, perhaps jeopardizing the standardization and coordination efforts that had made the RLUs possible in the first place. However, the decentralized supply chain case reveals the validity of the triple A supply chain in conjunction with the three Bs (bucks, bytes and boxes) and three I’s (identity, incentives and information) of supply chain management.

Something else

If you would like a harrowing hands-on account of relief efforts, the De-Risk blog has two excellent posts on where risk management is a matter of life and death part 1 and part 2, reporting from Oxfam’s work on risk managent in relief projects in Kenya and Sudan.

Reference

Gatignon, A., Van Wassenhove, L., & Charles, A. (2010). The Yogyakarta earthquake: Humanitarian relief through IFRC’s decentralized supply chain International Journal of Production Economics DOI: 10.1016/j.ijpe.2010.01.003

Author links

- insead.edu: Aline Gatignon

- insead.edu: Luk van Wassenhove

- univ-toulouse.fr: Aurelie Charles

Related

- husdal.com: Humanitarian and Military supply chains in Indonesia

- husdal.com: Emergency Logistics

- husdal.com: Pyramidal thoughts