A supply chain is never stronger than its weakest link, and that (having a weak link) is perhaps the greatest supply chain risk. Rigid supply chains are particularly weak, unlike flexible supply chains that can bend and adapt to new situations. Flexible supply chains can indeed “flex” their supply chain management muscles (pun intended) and show the strength that lies in them. With transportation being a key ingredient in any supply chain, much of this strength comes from flexibility in transportation, that is flexibility in node, in link and in time, as Mohamed M. Naim, Andrew T. Potter, Robert J. Mason and Nicola Bateman write in their 2006 article on the role of transport flexibility in logistics provision. Adding flexibility reduces supply chain uncertainty and takes away many supply chain risks.

A supply chain is never stronger than its weakest link, and that (having a weak link) is perhaps the greatest supply chain risk. Rigid supply chains are particularly weak, unlike flexible supply chains that can bend and adapt to new situations. Flexible supply chains can indeed “flex” their supply chain management muscles (pun intended) and show the strength that lies in them. With transportation being a key ingredient in any supply chain, much of this strength comes from flexibility in transportation, that is flexibility in node, in link and in time, as Mohamed M. Naim, Andrew T. Potter, Robert J. Mason and Nicola Bateman write in their 2006 article on the role of transport flexibility in logistics provision. Adding flexibility reduces supply chain uncertainty and takes away many supply chain risks.

Flexibility x 3

Transportation is a key function in the supply chain as it acts as a physical link between customers and suppliers, enabling the flow of materials and resource. shippers often presume that transportation will respond to short-term demand changes and, in particular, be willing to accommodate uncertainties, which they do, but this accommodation comes at a cost. Flexibility, thus, should rather be a proactive characteristic that is embedded into the carrier organization’s strategy, behavior, processes and technology. However, such flexibility can only come about if supplier, carrier and customer collaborate.

Collaboration for flexibility

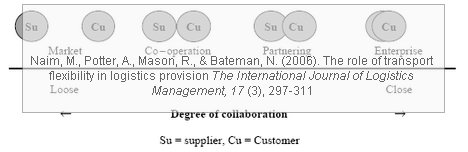

This collaboration, so they say, needs to be both vertical and lateral:

While much of the research on collaboration has been of the “vertical” nature there is also the need to consider “horizontal” collaboration. Such collaboration may be referred to as alliances, where competitors look for new opportunities, or clusters, where organisations with complementary capabilities offer a greater degree of service scope.

Initially, this is a collaboration between two parties only, supplier and customer:

The degree or stages of collaboration are very similar to the cooperative strategies employed by Child et al. (2005).

Types of collaboration

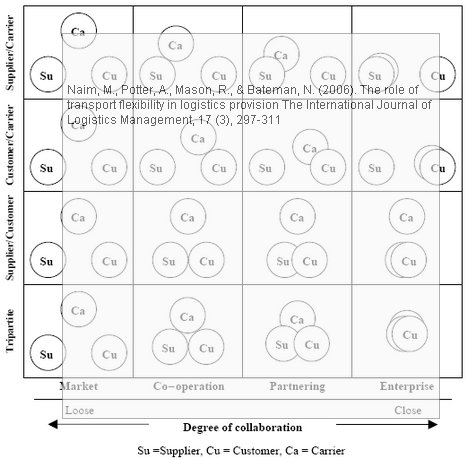

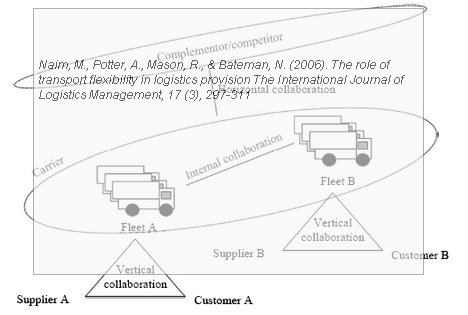

Following Bask (2001), who put forward the idea that there is a triangle of dyadic relationships between supplier, customer and carrier, the authors suggest that we ought to

reconsider the classic dyadic relationship and re-articulate the collaboration models into a tripartite form to consider the carrier, supplier and customer.

Taking the four degrees of collaboration and the three dyadic relationships into account, 12 constellations are possible:

I think the figure speaks for itself.

Types of flexibility

After consulting the literature, the authors come up with a long list of possible flexibility assets

Internal flexibility

- Mode

- Ability to provide different modes of transport

- Fleet

- Ability to provide different vehicle types to carry different goods

- Vehicle

- Ability to configure vehicles to carry products of different types or to cater for different loading facilities

- Node

- Ability to plan, approve and implement new nodes in the network

- Link

- Ability to establish new links between nodes

- Temporal

- Ability to sequence infrastructure investment

- Capacity

- Ability to accommodate variations or changes in traffic demand

- Routing

- Ability to accommodate different routes

- Communication

- Ability to manage a range of different information types

External flexibility

- Product

- The range and ability to accommodate the provision of new transport services

- Mix

- The range and ability to change the transport services currently being provided

- Volume

- The range of and ability to accommodate changes in transport demand

- Delivery

- The range of and ability to change delivery dates

- Access

- The ability to provide extensive distribution coverage

I think the list captures the essential types of flexibility that are or should be inherent in transportation.

Types of logistics services

The types of flexibility then play a major in the type of logistics services that can be provided by a carrier:

- Routine logistics services, with little or no flexibility other than adapting to external circumstances.

- Standard logistics services, with some degree of flexibility, particularly in terms of delivery and mix.

- Customized logistics services, with a full range of flexibility types.

Flexibility and collaboration

In the end, the authors develop a figure based on the above:

I instantly like papers that convey their message through good illustrations. A picture tells more than words, and this figure does that, showing the vertical collaboration with the supply chain, and the lateral collaboration that exists on the 3PL side.

Conclusion

I like this paper, because it clearly shows the role of freight carriers in reducing supply chain risk by achieving the necessary flexibility in supply chains. It is interesting to note that they use the term transport(ation) flexibility or logistics flexibility, signifying a marked difference between logistics and supply chain mangement. It also carries a notion of the gap that exists between managing and operating a supply chain. What this paper also does is highlight some of the possible metrics of transport flexibility, based on a collaborative approach to relationships between carrier, supplier and customer.

Reference

Naim, M., Potter, A., Mason, R., & Bateman, N. (2006). The role of transport flexibility in logistics provision The International Journal of Logistics Management, 17 (3), 297-311 DOI: 10.1108/09574090610717491

Author links

- cardiff.ac.uk: Mohamed Naim

- cardiff.ac.uk: Andrew Potter

- cardiff.ac.uk: Robert J Mason

- lboro.ac.uk: Nicola Bateman

Related

- husdal.com: Fighting transportation uncertainty in supply chains

- husdal.com: What kind of supplychainist are you?

- husdal.com: Supply chain mangement – fact or fiction?