Resilience. That seems to be the buzzword these days. It seems to be making its way not only around the blogosphere, like on Ken Simpson’s blog, but also in the supply chain and logistics literature. In Ensuring supply chain resilience: Development of a conceptual framework, just out in the Journal of Business Logistics, Timothy J Pettit, Joseph Fiksel and Keely L Croxton develop a concept of supply chain resilience based on an extensive literature search and a focus group study. And quite frankly, this is one of the the better and most comprehensive frameworks for understanding resilience that I have seen, drawing on the quintessence of many years of supply chain risk research. Resilience, in essence, is bridging vulnerabilities by honing capabilities.

Resilience. That seems to be the buzzword these days. It seems to be making its way not only around the blogosphere, like on Ken Simpson’s blog, but also in the supply chain and logistics literature. In Ensuring supply chain resilience: Development of a conceptual framework, just out in the Journal of Business Logistics, Timothy J Pettit, Joseph Fiksel and Keely L Croxton develop a concept of supply chain resilience based on an extensive literature search and a focus group study. And quite frankly, this is one of the the better and most comprehensive frameworks for understanding resilience that I have seen, drawing on the quintessence of many years of supply chain risk research. Resilience, in essence, is bridging vulnerabilities by honing capabilities.

It started with a PhD

Like so many other seminal articles, this one too started off with a PhD. Timothy J Pettit was awarded the Doctoral Dissertation Award Winner by the Council of Supply Chain Management Professionals CSCMP for his dissertation titled Supply Chain Resilience: Development of a Conceptual Framework, an Assessment Tool and an Implementation Process, which forms the basis for much of this article. It is well worth reading the dissertation for a fuller understanding of the article. It is available for download below.

Resilience

The authors start out their discussion of resilience by quoting three definitions or approaches to resilience and their thoughts on these, and it is the combination of these approaches that makes up their view of resilience.

First, the traditional engineering approach:

“the tendency of a material to return to its original shape after the removal of a stress that has produced elastic strain”

It may be beneficial for a supply chain not to return to its original shape following a disruption, but rather to learn from the disturbance and adapt into a new configuration.

This is something can be clearly seen in Sheffi’s disruption profile that has been mentioned time and again on this blog, where any disturbance will have a long-term effect.

Then the ecological approach:

“the ability for an ecosystem to rebound from a disturbance while maintaining diversity, integrity, and ecological processes”

The concept of adaptability is crucial to living systems, and supply chains may be seen as a network of living systems.

The supply chain life cycle is not a new concept, but it is nice to see an article picking up on a notion and referring to the same article that I used in my book chapter on Virtual Enterprise Networks.

Finally, the organizational approach:

“more than education, more than experience, more than training, a person’s level of resilience will determine who succeeds and who fails”

Creating resilient leaders “is the best way to ensure that your organization will prosper in a very chaotic and uncertain future,” and those resilient organizations consistently outlast their less resilient competitors.

Resilient leaders may not be at the forefront of the New Zealand research project on Resilient Organisations, but resilient leaders will not be tempted to stick their heads in the sand, as Alex Fullick writes about.

The resilience model

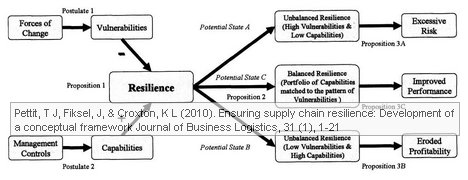

Two postulations and five propositions form the resilience model:

- Forces of change create supply chain vulnerabilities. Supply chain vulnerabilities are the fundamental factors that makes an enterprise susceptible to disruptions.

- Management controls create supply chain capabilities. Supply chain capabilities are attributes that enable an enterprise to anticipate and overcome disruptions.

- Supply chain resilience increases as capabilities increase and vulnerabilities decrease.

- Linkages exist between each vulnerability and a specific set of capabilities that can directly improve balanced resilience.

- Excessive vulnerabilities relative to capabilities will result in excessive risk.

- Excessive capabilities relative to vulnerabilities will erode profitability.

- Supply chain performance improves when capabilities and vulnerabilities are more balanced.

Graphically it looks like this:

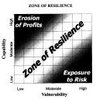

I find this a very simple, yet extremely elegant model, where the basic assumption is that capabilities must match, and where an overinvestment in capabilities (that are useful but not needed) will erode profits just as much as a lack of capabilities (that should have been there, but that have been neglected) will increase the exposure to risks.

Vulnerabilities and capabilities

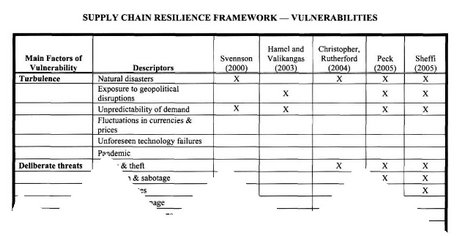

Seven factors that influence vulnerability and fourteen capability factors were further analyzed using a focus group. First, the vulnerability factors, in order of importance:

- Turbulence

- Frequent and uncontrollable changes in the external environment

- Deliberate threats

- Intentional attacks in order to cause harm

- Connectivity

- Degree of interdependence and reliance on outside entities

- Sensitivity

- Importance of carefully controlled environments for product integrity

- Resource Limits

- Constraints on output because of unavailability of input

- Supplier/customer disruptions

- Susceptibility of suppliers and customers to outside forces

- External pressures

- Influences that create constraints or barriers

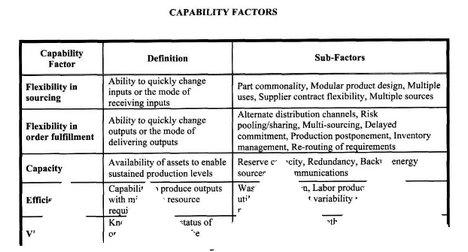

Likewise, factors that influence capabilities:

- Flexibility in order fulfillment

- Ability to quickly change outputs or mode of delivering outputs

- Flexibility in Sourcing

- Ability to quickly change inputs or mode of receiving outputs

- Organization

- Human resources, policies and corporate culture

- Visibility

- Knowledge of the status of operating assets

- Anticipation

- Ability to discern future events or possibilities

- Recovery

- Ability to return to normal operational state rapidly

- Security

- Defense against deliberate attack

- Capacity

- Ability to sustain or increase production levels

- Collaboration

- Ability to work with other entities for mutual benefit

- Dispersion

- Distribution and decentralization of assets

- Financial strength

- Ability to absorb fluctuations in cash flow

- Efficiency

- Ability to produce outputs with minimum resource requirements

While the two first capabilities are no surprise, I find it interesting that efficiency ranks low since I would expect the presence of minimal resources during a disruption, i.e. make do with what you have. On the other hand, in such circumstances, flexibility is probably more important, and rightly so. Note also that financial strength is not a prerequisite for resilience.

I highly recommend my readers to view the complete survey and results in the aforementioned PhD dissertation on Supply Chain Resilience by Timothy J Pettit, available for download below..

Where to find what

Two things are great about this article

For the supply chain professional, the list of vulnerability and capability factors is of great help when analyzing one’s own resilience, and thus managerial implications.

For the supply chain academic, the same factors are also listed with their matching literature reference, making it easy to find out which author that describes what.

This is why I instantly fell in love with this paper and why I decided to review it as soon as I learned about its existence today.

Conclusion

Seldom have I seen such a comprehensive yet to the point article on supply chain resilience that satisfies both academia and the industry at the same time. Usually the weight is on either industry or academia. For sure, this will become one of the articles that I will refer to in my reference lists time and again in my future writings.

Reference

Pettit, T J, Fiksel, J, & Croxton, K L (2010). Ensuring supply chain resilience: Development of a conceptual framework Journal of Business Logistics, 31 (1), 1-21 ProQuest document ID: 2020607081

Author links

- linkedin.com: Timothy J Pettit

- linkedin.com: Joseph Fiksel

- linkedin.com: Keely Croxton

Downloads

- researchgate.net: Supply chain resilience: Development of a conceptual framework, an assessment tool and an implementation process

(PhD dissertation by Timothy J Pettit)

Related

- husdal.com: Resilience revisited