“The world is at risk and the supply chain is not exempt.” Are you scared? “Supply risk used to be defined as the potential for strikes by transport workers, fires at a key supplier’s plant, or missed deliveries. That simple vision no longer applies.” These pompous words mark the beginning of today’s article, Supply chain risk in an uncertain global supply chain environment, written by Jack Barry in 2004. His article raises some essential supply chain questions, and reminds us that global sourcing may be low cost, but not low risk.

“The world is at risk and the supply chain is not exempt.” Are you scared? “Supply risk used to be defined as the potential for strikes by transport workers, fires at a key supplier’s plant, or missed deliveries. That simple vision no longer applies.” These pompous words mark the beginning of today’s article, Supply chain risk in an uncertain global supply chain environment, written by Jack Barry in 2004. His article raises some essential supply chain questions, and reminds us that global sourcing may be low cost, but not low risk.

A wake-up call

This short, succinct, two-page piece is the introduction to a special issue on Logistics and the supply chain risk and uncertainty in IJPDLM, the International Journal of Physical Distribution & Logistics Management. In the article, Barry raises some fundamental concerns about the current trend towards global outsourcing and its consequences. Yes, it may be cutting the costs, but it is not cutting the risks. And risk is one thing a company cannot outsource. As Martin Christopher notes in his book chapter on managing risk in the supply chain:

The trend towards just in time and lean practices

>>> efficiency rather than effectivenessThe trend towards reducing costs

>>> globalization, more complex and longer supply chainsThe trend towards economies of scale

>>> centralized distribution and manufacturing

>>> lower costs, but also less flexibilityThe trend towards outsourcing of non-core business activities

>>> loss of control when it is most neededThe trend towards consolidation of suppliers

>>> increased potential for disruptions

Globalization, for all its benefits, does come at a cost, and Barry’s message is that it is about time that we acknowledge and consider this cost.

An enterprise may have lowest over-all costs in a stable world environment, but may also have the highest level of risk – if any one of the multiple gating factors kink up an elongated global supply chain!

The Nokia-Ericsson plant fire is the classic textbook example of a gating factor kinking up a supply chain.

Food for thought

Barry raises some important questions in his article, questions every manager and CEO should ponder on a regular basis. Below are some of them.

Who are the specific suppliers, materials, and services that are at risk, especially those global sources of supply?

Barry is spot on when he says that effective supply risk management requires identifying an monetizing risk events, establishing the probability of occurrence, and developing contingencies for alternative sources of supply.

What is the impact of the compromise of intellectual properties from global sourcing?

Another important message by Barry. What do you do when subcontractors become suppliers, then partners, and, finally, competitors – all fostered by the transfer of technology for short-term cost advantage. Is it really worth it in the long run? Remember: The wrong people can ruin a right supply chain.

What are the consequences of the lack of seamless global e-commerce?

Current technology applications, so Barry says, are islands of digital standards surrounded by seas of non-compatibility. I guess he’s right. Each supply chain consultancy firm appears to have their own proprietary software solutions, which of course are promoted as being better than their competitor’s. But do we need them all? How long can the supply chain afford the buffers of excesses required by just-in-case technology and sold by mischievous ERP consultants?

Further reading required

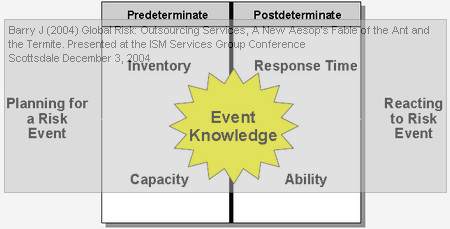

The article is very short and Barry does not elaborate much around his key points, besides simply posing the questions. Fortunately, I did find a presentation he made at the Institute for Supply Management Services Group Conference in 2004, titled Global Risk: Outsourcing Services, A New Aesop’s Fable of the Ant and the Termite. Here he presented his article and his thoughts behind it. The slides I liked best are:

The benefits of globalisation:

India develops my software

Ireland manages my customer service

Taiwan does my testing

Mexico performs piece labor

Germany balances my finances

Israel does my clinical research

… my supply sources are global.

>>> I have the lowest overall cost of services

The risks of globalization:

India owns my IT process and innovation

Ireland is between me and my customers

Taiwan controls my quality control

Mexico dominates my capacity curve

Germany leverages my finances

Israel has first views of my innovation

… my supply sources may be beyond my laws and conventions.

>>> I have the highest level of risk to continued operations

Another slide I found particularly intriguing is this one:

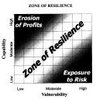

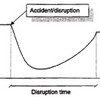

This figure perfectly combines contingency and mitigation strategies for dealing with risk, and links them with supply chain variables like capacity and inventory.

Critique

For all its brevity, the articles does raise some important issues. It would fit well as a column in the Wall Street Journal, Harvard Business Review or MIT Sloan Management Review. It is perhaps not so well-suited alongside the other articles in this special issue of IJPDLM. That said, it serves its function well. After all, I did spend an entire day writing this post and discovered that there was more to this article than the mere two pages it is written on.

Reference

Barry, J. (2004). Supply chain risk in an uncertain global supply chain environment International Journal of Physical Distribution & Logistics Management, 34 (9), 695-697 DOI: 10.1108/09600030410567469

Author link

- linkedin.com: Jack Barry

Related

- husdal.com: Can you outsource risk?

- husdal.com: Supply chain vulnerability – a global risk?