What are the most common supply chain and logistics risks that businesses and logistics providers have to deal with? Here is a study that provides the most complete answer to that question that I have seen to date. Risikomanagement in der Supply Chain – Status Quo und Herausforderungen aus Industrie-, Handels- und Dienstleisterperspektive by Hans-Christian Pfohl, Philipp Gallus and Holger Köhler is a meticulous study from Germany that speaks for itself in describing which risks that have which probability and which impact among businesses and among logistics providers. Note that I use supply chain and logistics risks. That is because this study separates business risks from logistics providers risk, and that is a novel approach I haven’t seen too often.

What are the most common supply chain and logistics risks that businesses and logistics providers have to deal with? Here is a study that provides the most complete answer to that question that I have seen to date. Risikomanagement in der Supply Chain – Status Quo und Herausforderungen aus Industrie-, Handels- und Dienstleisterperspektive by Hans-Christian Pfohl, Philipp Gallus and Holger Köhler is a meticulous study from Germany that speaks for itself in describing which risks that have which probability and which impact among businesses and among logistics providers. Note that I use supply chain and logistics risks. That is because this study separates business risks from logistics providers risk, and that is a novel approach I haven’t seen too often.

Hitting the nail on the head

The study splits supply chain risks in risk and consequences faced by businesses in their supply chain from risks and impacts faced by logistics providers in the supply chain. In my opinion that is the right way to do it, because the importance of transportation operations is often overlooked in supply chain management. This study highlights the role of logistics very well and is one of the very few where I have seen it done.

All-encompassing

This is a thorough study, and my review can only skip the surface of this book chapter, which unfortunately, for many of my readers, is in German. That said, I will do my best in providing a translation to the opening question, namely What are the most common supply chain and logistics risks that businesses and logistics providers have to deal with? Below is a collection of figures from the book chapter, which I have translated the best I can, so that Non-German-speaking readers can make use of the findings in this study. There is a lot more to this chapter than the figures below, but that will ave to wait for another (rainy day when I have the time to write another) post.

Logistics and supply chain risks – company perspective

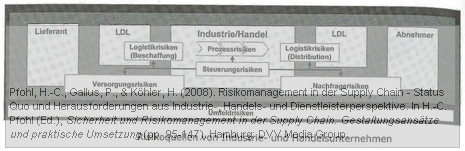

The model framework follows the traditional division of risk sources in supply risks (Versorgungsrisiken) related to the supplier (Lieferant), demand risks (Nachfragerisiken) related to the customer (Abhehmer), process and control risks (Prozessrisiken/ Steuerungsrisiken), and external risks (Umfeldrisiken). In addition, there are two logistics risks (Logistikrisiken) related to the logistics provider (LDL), one related to sourcing (Beschaffung) and one related to distribution (Distribution). These risks are then evaluated, first from the company supply chain perspective, and from the logistics provider perspective

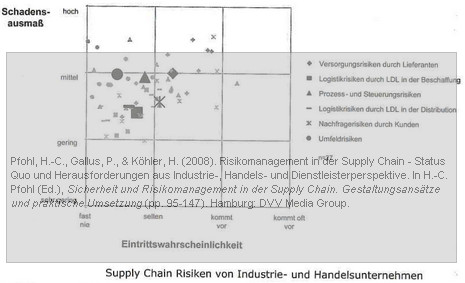

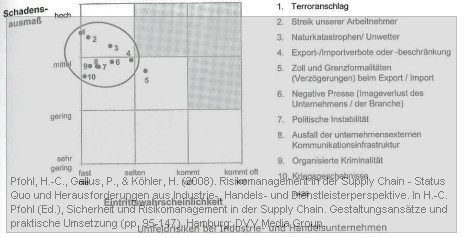

Supply chain risks – probability and impact

The risk matrix shows the overall picture of supply chain risks in the survey, with the probability (Eintrittswahrsheinlichkeit) increasing from left to right, and the impact (Schadensausmaß) increasing from bottom to top.

- Supply risks (diamond)

- Sourcing-related logistics risks (square)

- Process and Control risks (triangle)

- Distribution-related logistics risks (dash)

- Demand risks (cross)

- External risks (circle)

Each of the risk sources is covered in detail in the following figures. Albeit a small sample, and perhaps not generalizable, it is still interesting to read what the companies that were surveyed list as their most imminent risks.

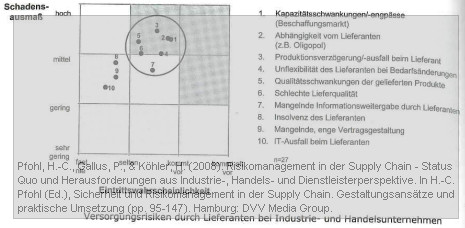

Supply risks

- Capacity fluctuations/bottlenecks in the supply market

- Dependence on a certain supplier

- Production delays or disruptions

- Inflexibility of supplier when faced with last minute order changes

- Varying quality

- Low quality

- Crucial information is not passed on to purchaser

- Supplier insolvency

- Rigid contracts

- Outage of IT-systems

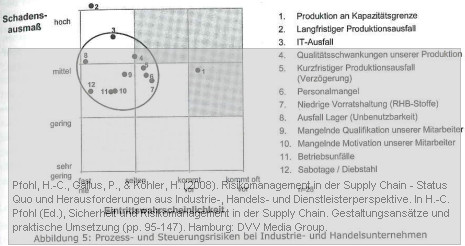

Process and control risk

- Production close to capacity limit

- Long-term production outage

- Outage of IT-system

- Varying quality of products made

- Short-term production outage or delays in production

- Lack of personnel

- Low inventory of raw materials

- Inventory outage (facilities unusable)

- Personnel lacks qualifications

- Personnel lacks motivation

- Accidents

- Malicious acts/sabotage/theft

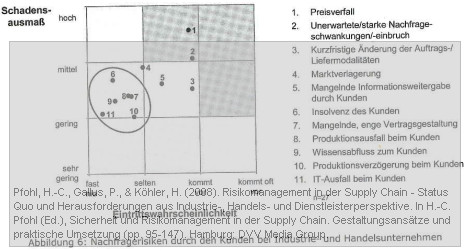

Demand risks

- Price slump

- Unexpected demand fluctuations or total failure

- Last-minute changes in order specifications

- Market segment changes

- Necessary information is not passed on by customer

- Customer insolvency

- Rigid contracts

- Production outage at customer

- Loss of intellectual property

- Production disruption/delay at customer

- Outage of IT-systems at customer

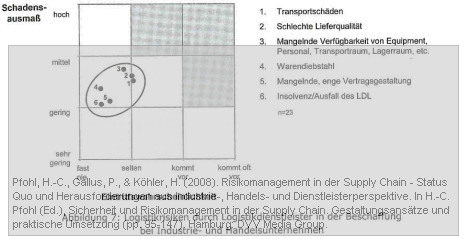

Sourcing logistics risks

- Breakage during transport

- Low quality transport

- Lack of personnel, equipment, vehicle and storage space

- Theft

- Rigid contracts

- Insolvency of logistics provider

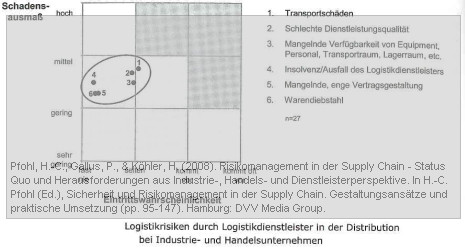

Distribution logistics risks

- Breakage during transport

- Low quality transport

- Lack of personnel, equipment, vehicle and storage space

- Insolvency of logistics provider

- Rigid contracts

- Theft

External risks

- Terrorist attack

- Strikes and other labor conflicts

- Natural disasters

- Export or import restrictions

- Delays or other formality (“red tape”) issues with customs clearance

- Negative PR, loss of brand reputation

- Political instability

- Outage of ICT-systems external to company

- Organized crime

- War

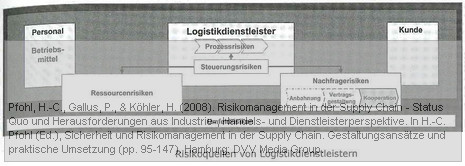

Logistics and supply chain risks – provider perspective

The framework for the risk sources for the logistics provider follows the same principle as the framework for the supply chain risks, but now the logistics provider is center stage, having process and control risks, with a supply side (Resourcenrisiken) and a demand side (Nachfragerisiken).

The supply side consists of personnel (Personal) and operational means (Betriebsmittel), or transportation means. The customer (Kunde) makes up the demand side, and the demand risks are separated further into initiation (Anbahnung), contract design (Vertragsgestaltung) and cooperation (Kooperation).

The supply side consists of personnel (Personal) and operational means (Betriebsmittel), or transportation means. The customer (Kunde) makes up the demand side, and the demand risks are separated further into initiation (Anbahnung), contract design (Vertragsgestaltung) and cooperation (Kooperation).

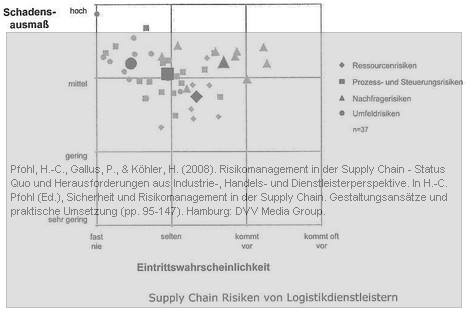

Logistics risks – probability and impact

The risk matrix shows the overall picture of logistics risks in the survey, with the probability (Eintrittswahrsheinlichkeit) increasing from left to right, and the impact (Schadensausmaß) increasing from bottom to top.

- Supply risks (diamond)

- Process and control risks (square)

- Demand risks (cross)

- External risks (circle)

Each of the risk sources is covered in detail in the following figures. Again, a small sample, and perhaps not generalizable, it is still interesting to read what the logistics providers that were surveyed list as their most imminent risks.

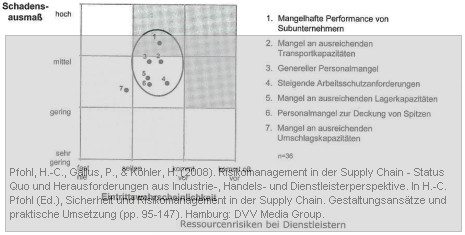

Supply risk

- Sub-performing sub-contractor

- Lack of sufficient transport capacity

- General lack of personnel

- More and more HES regulations, requirements and restrictions

- Lack of (intermediate) storage space

- Lack of personnel during peak operations

- Lack of sufficient transfer capacity (mode or means change)

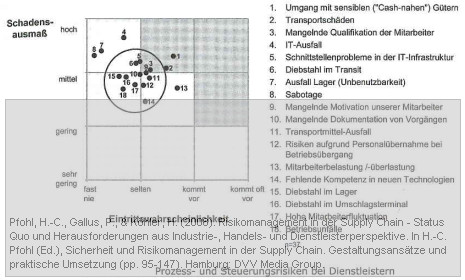

Processs and control risks

- Handling of sensitive goods

- Breakage during transport

- Personnel lacks qualification

- Outage of IT-systems

- Interface issues between different IT-systems

- Theft

- Inventory outage (facilities unusable)

- Malicious acts or sabotage

- Personnel lacks motivation

- Lack of procedural documentation

- Outage of transport means (vehicles)

- HR-issues during/after company takeover/merger

- Overworked personnel

- Lack of competence using new/latest technology

- Theft at warehouse or storage facility

- Theft at transfer facility

- High turnover of personnel

- Accidents

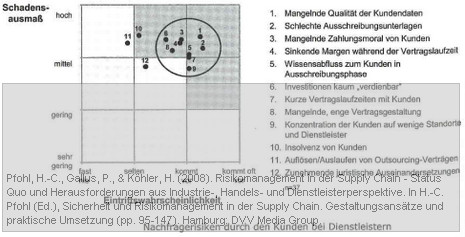

Demand risks

- Deficiencies in customer data/information

- Deficiencies in tender documents

- Delinquent customer payments

- Decreasing profit margins during contract period

- Loss of intellectual property during tender phase

- No/little return on investment

- Short contract period

- Rigid contracts

- Clustered location of customers

- Customer insolvency

- Termination of outsourced services

- Increasing legal arguments

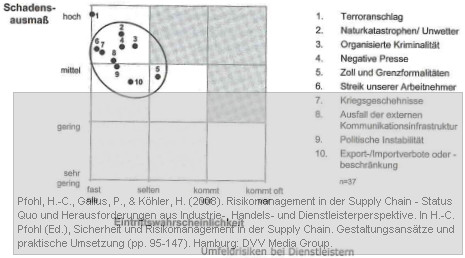

External risks

- Terrorist attack

- Natural disasters

- Organized crime

- Negative PR, loss of brand reputation

- Delays or other formality (“red tape”) issues with customs clearance

- Strikes and other labor conflicts

- War

- Outage of ICT-systems external to company

- Political instability

- Export or import restrictions

Critique

In my humble opinion, this is, by far, the most comprehensive overview of logistics and supply chain risks that I have seen to date. I already said that above. What I like about this chapter is the framework that shows how supply chain risks are intertwined with logistics or transportation risks, and that one cannot be treated without the other. The framework allows for a holistic perspective, where not only the risk realm of the supply chain is viewed end-to-end, but where the risk realm of every individual contributor to the supply chain is incorporated. It’s a shame that this is available in German only.

Reference

Pfohl, H.-C., Gallus, P., & Köhler, H. (2008). Risikomanagement in der Supply Chain – Status Quo und Herausforderungen aus Industrie-, Handels- und Dienstleisterperspektive. In H.-C. Pfohl (Ed.), Sicherheit und Risikomanagement in der Supply Chain. Gestaltungsansätze und praktische Umsetzung (pp. 95-147). Hamburg: DVV Media Group.

Author links

- researchgate.net: Hans-Christian Pfohl

- unknown: Philipp Gallus

- xing.com: Holger Köhler

Related

This is not the first time these authors appear on my blog. In a recent article on the state of the art in supply chain risk management the authors identify security, resilience, risk, disturbance and disruption is key factors that need to be considered in supply chain risk management.