Christmas. Toys. Two things that belong together. But it isn’t always a happy story. Not only do seasons play a big role in supply and demand, so do fads; what is popular today may not be so anymore tomorrow, and as if that wasn’t enough to cope with, product safety issues are probably keeping more CEOs up at night than the unpredictability of sales figures. The year 2007 will be particularly remembered as the year the toy industry was shaken by a seemingly endless stream of recalls. Way ahead of this, in 2001, M Eric Johnson wrote Learning From Toys: Lessons in Managing Supply Chain Risk from the Toy Industry. Here he shows that how the toy industry handles supply chain risk is applicable to many other industries as well.

Christmas. Toys. Two things that belong together. But it isn’t always a happy story. Not only do seasons play a big role in supply and demand, so do fads; what is popular today may not be so anymore tomorrow, and as if that wasn’t enough to cope with, product safety issues are probably keeping more CEOs up at night than the unpredictability of sales figures. The year 2007 will be particularly remembered as the year the toy industry was shaken by a seemingly endless stream of recalls. Way ahead of this, in 2001, M Eric Johnson wrote Learning From Toys: Lessons in Managing Supply Chain Risk from the Toy Industry. Here he shows that how the toy industry handles supply chain risk is applicable to many other industries as well.

Daunting

While few of the risks faced by toy makers are unique to the industry, the combination of risks is daunting, Johnson says.

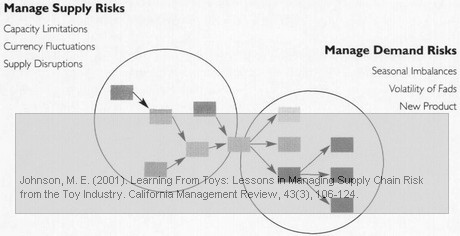

There are risks associated with product demand including seasonality, volatility of fads, new product adoptions, and short product life. The public’s perception of safety and toy company ethics (such as the use of child labor) are also elements of demand risk (not to mention the risk of litigation). Then there are the risks of product supply such as manufacturing and logistics capacity during crunch periods. With supply chains that extend into Asia, there are also substantial currency and political risks that can change product cost or disrupt supply. Moreover, the long lead times between demand and supply exacerbate all of the risks.

Essentially, again according to Johnson, it’s all about supply and demand:

Managing demand

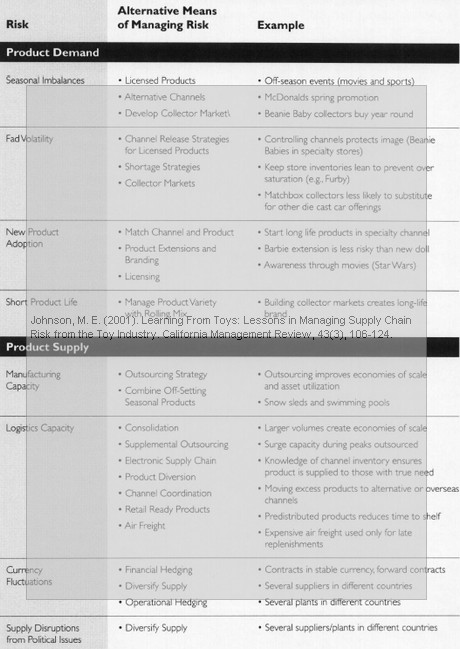

- Reduce Seasonality and New Product Adoption Risk through Licensing

- Increase Product Life and Lifetime Sales by Matching Product and Channel Strategies

- Reduce Seasonality by Increasing Number of Channels

- Smooth Demand and Build Longer Life Products through Variety Strategies

Managing supply

- Reduce Capacity Risks by Outsourcing and Building a Flexible Web of Partners

- Improve Supply/Demand Matching through Information, Air Freight, and Warehouse Consolidation

- Reduce Currency and Political Risk through Operational Hedging

This table summarized the above, with examples:

Critique

At it’s inception it was a timely article; it still is. It is well researched and well written, and one would expect nothing less from a professor Tuck School of Business at Dartmouth. What is particularly enriching are the examples and practical experiences from a wide range of toy makers. It is perhaps not the article that is most easily translated into an action plan, but it is an article that leaves your mind pondering. Obviously, the toy industry is not all about fun, it sis serious business as well, let alone risky business.

Reference

M Eric Johnson (2001). Learning From Toys: Lessons in Managing Supply Chain Risk from the Toy Industry California Management Review, 43 (3), 106-124. Proquest ID: 74766340

Author link

- linkedin.com: M Eric Johnson

Related posts

- husdal.com: Can you outsource risk?

- husdal.com: Outsourcing – risking it all?

- husdal.com: Lessons from the China recall crisis