The risk perception an individual supply chain professional has influences the risk management strategies this individual chooses to mitigate the effect of potential supply chain disruptions. But does risk perception influence the occurrence of disruptions? In other words, if you think you are at risk, are you actually more likely to experience disruptions than if you think you are not at risk? Enhancing supply chain resilience with flexibility and redundancy is one way to counter supply chain disruptions. But do the chosen resilience measures actually play a moderating role in reducing the frequency of supply chain disruptions? That is what George Zsidisin and Stephan Wagner investigate in their newest article, Do Perceptions Become Reality? The Moderating Role of Supply Chain Resiliency on Disruption Occurrence. This article paints an interesting picture of how supply chain professionals view risk, which risk they perceive and what they do in reaction to these risks.

The risk perception an individual supply chain professional has influences the risk management strategies this individual chooses to mitigate the effect of potential supply chain disruptions. But does risk perception influence the occurrence of disruptions? In other words, if you think you are at risk, are you actually more likely to experience disruptions than if you think you are not at risk? Enhancing supply chain resilience with flexibility and redundancy is one way to counter supply chain disruptions. But do the chosen resilience measures actually play a moderating role in reducing the frequency of supply chain disruptions? That is what George Zsidisin and Stephan Wagner investigate in their newest article, Do Perceptions Become Reality? The Moderating Role of Supply Chain Resiliency on Disruption Occurrence. This article paints an interesting picture of how supply chain professionals view risk, which risk they perceive and what they do in reaction to these risks.

Supply-side only

It must be said that this article looks exclusively at risk sources on the supply side of the supply chain. While this is perhaps a small limitation as to the number and direction of possible risk sources, it is often the possible disruptions on the supply side that causes most concern, not the demand side. .

Supplier – supply market – supply chain

The supplier risk source consists of potential problems associated with a specific supplier, its management, and systems. Supply market risk sources entail potential problems that exist with the supply market in general – not necessarily only with a specific supplier. The extended extended supply chain risk sources consist of characteristics associated with sourcing from suppliers in locations that are a far proximity to the buying firm’s operations. No less than 14 items were examined, grouped into factors related to the individual supplier, the supply market and the extended supply chain.

The factors listed below were ranked on a 1 to 5 scale by the respondents with a question like: “When making sourcing or supply chain management decisions (for a certain product), to what extent are you are you concerned about said factors, which may contribute to supply chain risk?”, where 1 is “not at all concerned” and 5 is “extremely concerned”.

Supplier

- Ineffective management in the supplier firm

- Financial instability or financial failure of supplier

- Supplier’s incorrect interpretation of requirements

- Incoming product quality problems

- Labor/management porblems at supplier

- Problems in electronic sharing of information (EDI, ERP)

Supply market

- Lack of alternative suppliers

- Inability to influence suppliers

- Inability of suppliers to meet significant increases in required volume

Extended supply chain

- Transportation disruptions in inbound supply channels

- Variability in transportation times in inbound supply chains

- Political instability affecting suppliers’ operations

- Natural disasters affecting suppliers’ operations

- Long distance between company and supplier

The factors above are listed in order of response significance, suggesting that

- Ineffective management in the supplier firm

- Lack of alternative suppliers

- Transportation disruptions in inbound supply channels

are the most important risk factors

Flexibility and redundancy

On the resilience side, flexibility and redundancy are seen as key drivers or contributors for resilience. Personally, I would want to include adaptive capacity and organizational learning as well, albeit for the supply side alone, flexibility and redundancy are perhaps sufficient enough? The factor flexibility consists of auditing supplier processes, monitoring supplier financial conditions, and certifying suppliers. In contrast, the items loading on the second factor, redundancy, includes using dual or multiple supply sources, ensuring excess supplier capacity exists, having supply continuity plans in place, requiring suppliers to report disruptions, and having suppliers hold inventory to prevent stockouts.

The factors listed below were ranked on a 1 to 5 scale by the respondents with a question like: “To what degree do you use said practices specifically to manage supply chain risk for a certain product”, where 1 is “not at all” and 5 is “very high”.

Flexibility

- Audit suppliers’ internal systems and processes

- Monitor the financial condition of suppliers

- Supplier certification program

Redundancy

- Dual or multiple supply sources

- Ensure that excess supplier capacity exists to handle unplanned increase in demand

- Supply continuity/contingency plans

- Require supplier to immediately report disruptions regardless of (little or large) impact

- Require supplier to hold inventory to prevent stockout

The factors above are listed in order of response significance, suggesting that

- Audit suppliers’ internal systems and processes

- Dual or multiple supply sources

are the most important flexibility and redundancy factors

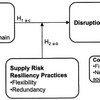

Research model

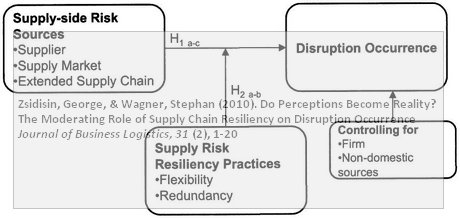

According to the authors, one purpose of the study is to investigate the relationship between management perceptions of supply risk and the frequency of experiencing the effects of supply disruptions, that is, whether supply management professionals’ judgements about risk stemming from various risk sources on the supply side are accurate and in fact materialize in disruptions.

H1 a – b Supply management professionals perceiving risk from (a) suppliers, (b) supply markets, and (c) extended supply chains, experience the effects of supply disruptions more frequently.

The other purpose of this study is to investigate whether the use of various supply chain resiliency practices serves a moderating role in reducing the frequency with which buying firms experience the effects of supply disruptions.

H2 a – b Supply management professionals that create supply chain resiliency through (a) flexibility and (b) redundancy in response to risk perceptions, experience the effects of supply disruptions less frequently.

The figure below illustrates the research model and the hypotheses.

And what did they find?

Results

One interesting finding in this study is that supply management professionals’ perceptions of risk from extended supply chains are negatively associated with disruption occurrence. In other words, the more at risk you think you are, the less often do you experience disruptions. Reason: If you consider yourself at risk, you are more likely to engage in proactive measures to reduce the probability of disruptions.

The authors also find that the supply resiliency practices of flexibility and redundancy do not moderate the relationship between the perceived risk from suppliers and disruption occurrence, and that the supply resiliency practice of flexibility does not moderate the relationship between perceived supply market risk and disruption occurrence. Disruptions occur, and neither flexibility nor redundancy can prevent them from happening. However, as they note, the biggest benefits to creating resiliency with flexibility appear to come from the risk that exists from extended supply chains. The constant monitoring of suppliers can uncover “hidden” problems that may exist when sourcing from far-off locations.

Pursuing supply chain resiliency through redundancy moderates the risk perceived from the supply market on disruption occurrence, while flexibility was not found to moderate the relationship between supply market risk and disruption occurrence. So redundancy works with a supply market, but not flexibility, or at least not to the same degree.

Reference

Zsidisin, George, & Wagner, Stephan (2010). Do Perceptions Become Reality? The Moderating Role of Supply Chain Resiliency on Disruption Occurrence Journal of Business Logistics, 31 (2), 1-20

Author links

- linkedin.com: George Zsidisin

- linkedin.com: Stephan Wagner

Read online

- findarticles.com: Do Perceptions Become Reality?

Critique

This article excellently highlights some of the supply-side risks that supply chain managers concern themselves with. While I agree with the second hypothesis, I found the argument of the first hypothesis a bit puzzling at first. That said, they did prove it wrong, and it is true that perceived disruption risk and actual disruption risk are often far from each other. On a sidenote, the article by Ellis, Henry and Shockley (2010) provide another interesting article on buyer perceptions of supply disruptions risk. I am also struggling with the factors used to describe flexibility. Admittedly, a supplier certification program may make it easy to switch