It’s amazing how supply chain risk papers appear in the unlikeliest of places, and today I discovered a paper from Iran by Ali Shemshadi, Mehran Toreihi, Hossein Shirazi, Mohammad Jafar Tarokh. It bears the title Supplier selection based on supplier risk: An ANP and fuzzy TOPSIS approach and is published in the Journal of Mathematics and Computer Science, not the obvious place where one would go to looking for a paper on supply chain risk. It is a highly quantitative paper, yet it seems to be very applicable in practice. The paper proposes a hybrid MCDM method based on ANP and Fuzzy TOPSIS to enhance previous solutions for the problem of selecting the best supplier from a set of potential alternatives based on a set of risk factors. That is an approach I haven’t seen before.

It’s amazing how supply chain risk papers appear in the unlikeliest of places, and today I discovered a paper from Iran by Ali Shemshadi, Mehran Toreihi, Hossein Shirazi, Mohammad Jafar Tarokh. It bears the title Supplier selection based on supplier risk: An ANP and fuzzy TOPSIS approach and is published in the Journal of Mathematics and Computer Science, not the obvious place where one would go to looking for a paper on supply chain risk. It is a highly quantitative paper, yet it seems to be very applicable in practice. The paper proposes a hybrid MCDM method based on ANP and Fuzzy TOPSIS to enhance previous solutions for the problem of selecting the best supplier from a set of potential alternatives based on a set of risk factors. That is an approach I haven’t seen before.

ANP, MCDM and TOPSIS

This is a highly quantitative paper, and while I know MCDM or multi-criteria decision-making, ANP and TOPSIS are unknown to me, but this is how the authors describe them:

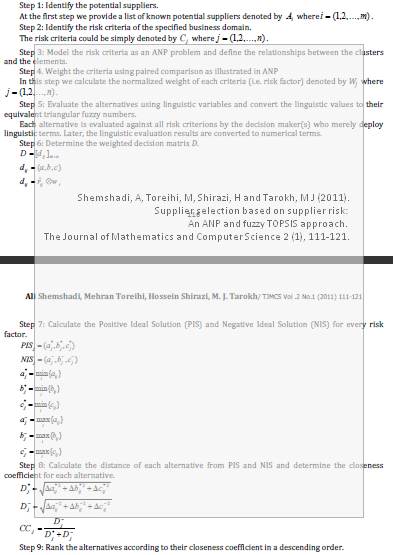

Analytic network process (ANP) is used for multi-criteria decision making (MCDM) problems. ANP is a general framework to deal with decision problems without making assumptions about the independence of the clusters or elements.

The TOPSIS (technique for order performance by similarity to ideal solution) is a solution to the MCDM problem. According to this technique, the best alternative would be the one that is nearest to the positive ideal solution (PIS) and farthest from the negative ideal solution (NIS). The PIS is a solution that maximizes the benefit criteria and minimizes the cost criteria and the NIS is vice versa.

The novel approach in this paper is that TOPSIS is extended into the realm of fuzzy numbers.

Supplier risk factors

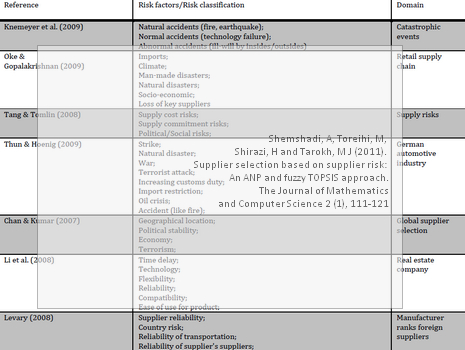

Albeit a bit brief, the literature review has managed to capture some every interesting papers on supplier risk:

Some of these are unknown to me, which is good, because it gives me more to research, and because it shows that I do not yet know everything there is to know about supply chain risk. Truth is, I probably never will, and that is how it should be.

Risk categorization

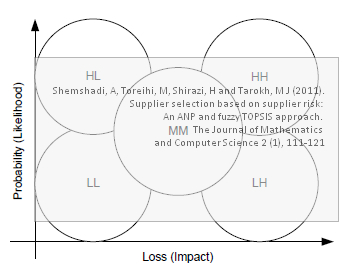

The author’s come up with five different risk (loss x probability) categories, based on Oke and Gopalakrishnan (2008), and I must admit that I missed that when I reviewed that paper:

Most risk will perhaps fall in the medium probability moderate impact category, while fewer risks will end up in the extreme categories, i.e. low probability and impact, high probability and impact, high probability low impact, and low probability high impact.

Step by step

Having no experience nor training in operations research, ANP or TOPSIS, I am somewhat at a loss as to their step by step calculations

but it does look correct as far as I can tell.

Types of risk

Interestingly, in their numerical example the authors classify risk according to five criteria:

- Country risk

- Financial risk

- Natural disasters

- Technology risk

- Delivery risk

However, it doesn’t say anywhere in the paper how they arrived at these criteria, either as an aggregation of their literature review, or directly from some of their references. That said, the list of risks does make sense, and maybe they were just used as an example?

Conclusion

This is a good paper, but it is a short paper, too short perhaps, as many of the assumptions are not explained, e.g. the five risk criteria. It should also have been subject to some more editorial oversight to weed out some misspellings and obvious grammatical errors and to improve the flow of sentences that are obvious even to me as a non-native English speaker. Still, it is far from the worst I have seen. That aside, although I am unable to follow their deductions to the letter, I still enjoyed their approach, which makes very much sense to me, despite my lack of understanding, and I hope the authors will elaborate more on this in a future paper. Another reason that makes the paper worthwhile is the literature list. Albeit the literature review itself appears overly cursory, I did find many supply risk papers in there that I hadn’t heard of before, which will add more files to my already bursting file cabinet and more papers on my “to review”-list.

Reference

Shemshadi, A, Toreihi, M, Shirazi, H and Tarokh, M J (2011). Supplier selection based on supplier risk: An ANP and fuzzy TOPSIS approach. The Journal of Mathematics and Computer Science 2 (1), 111-121.

Author links

- adelaide.edu.au: Ali Shemshadi

- linkedin.com: Mehran Toreihi

- acm.org: Hossein Shirazi

- researchgate.net: Mohammad Jafar Tarokh

Related post

- husdal.com: Risk-based classification of supplier risk