Historically, third-party logistics providers, or 3PLs, provided traditional logistics services, such as transportation and warehouse management and nothing more than that. However, the increased volume and scope of services demanded from 3PLs have given rise to their changing role, where today they are engaged in strategic coordination of their customers’ supply chain activities. So say Zach Zacharia, Nada Sanders and Nancy Nix in their most recent article on The Emerging Role of the Third-Party Logistics Provider (3PL) as an Orchestrator. Here they show how 3PLs have evolved from providing logistics capabilities to becoming orchestrators of supply chains that create and sustain a competitive advantage. The question is, what is it that defines an orchestrator? And, are 3Pls also becoming risk orchestrators?

Historically, third-party logistics providers, or 3PLs, provided traditional logistics services, such as transportation and warehouse management and nothing more than that. However, the increased volume and scope of services demanded from 3PLs have given rise to their changing role, where today they are engaged in strategic coordination of their customers’ supply chain activities. So say Zach Zacharia, Nada Sanders and Nancy Nix in their most recent article on The Emerging Role of the Third-Party Logistics Provider (3PL) as an Orchestrator. Here they show how 3PLs have evolved from providing logistics capabilities to becoming orchestrators of supply chains that create and sustain a competitive advantage. The question is, what is it that defines an orchestrator? And, are 3Pls also becoming risk orchestrators?

3PL – more than logistics

Orchestration can be defined as the activity of managing, coordinating, and focusing the value-creating network, and as entities that connect members of the supply chain, 3PLs serve a critical role responsible for achieving effective logistics integration. 3PLs have become the linchpin of the orchestration of supply chains, and they have become the glue that ties the individual supply chain actors together. In fact, 3PLs and the services they provide are perhaps the key ingredient in any supply chain, they are managers of the supply chain and they are eliminators of uncertainty in the supply chain.

Why outsource?

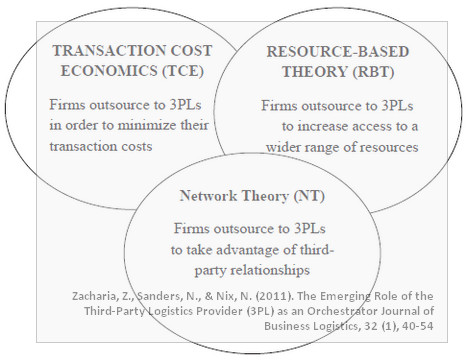

Contrary to my last post and the paper that simply lists the benefits of outsourcing,without further discussion or reasoning, this paper uses no less than three theoretical approaches as to determine the reason for why firms would outsource their logistics activities: Transaction cost economics (TCE), Resource-based theory (RBT) and Network theory (NT).

TCE theory states that a firm’s ownership decision is based on minimizing the sum of its transaction and production costs.

According to the RBT perspective, as a bundle of resources that are heterogeneously distributed across firms, with differences between them that persist over time.

In the NT perspective, outsourcing enables the firm to manage its supply chain as a single entity through the application of relationship building and network coordination.

This leads to the following three reasons for why firms would want to outsource and what they expect from it:

I think that merging these three frameworks does provide a rich backdrop for investigating the different roles a 3PL can assume in a supply chain. This is the first theoretical foundation of the article.

How outsource?

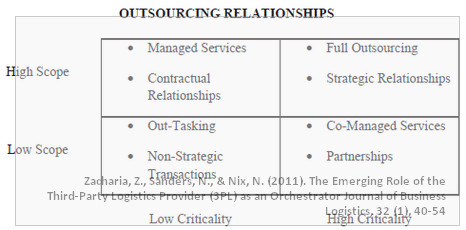

The second theoretical foundation used to describe logistics outsourcing looks at the scope and the criticality of the tasks outsourced. Scope can be defined as the breadth or degree of responsibility assigned to the 3PL. Criticality then is the importance of the outsourced task or function to the firm.

Depending on the range of the scope or the degree of the criticality, four types of relationships emerge, along with their associated logistics services:

Out-tasking, which involves outsourcing a specific task, such as inventory management, i.e. Non-strategic Transactions.

Co-managed services, which involves assigning a larger (and usual important) scope of the task or function to the 3PL, i.e. Partnerships.

Managed Services, where the 3PL designs, implements, and manages an end-to-end solution for a complete function, i.e. Contractual Relationships.

Full Outsourcing, where the 3PL is assigned total responsibility for the design, implementation, management, and often the strategic direction of the function, operation, or process being outsourced, i.e. Strategic Relationship.

Successful supply chains need successful logistics, and it is no surprise then that the contemporary role of the 3PL has moved from simple out-tasking to full outsourcing, or from the lower-left quadrant to the top-right quadrant of the figure above. That is the new role of 3PL providers. 3PLs are not just supply chain service providers, they are now supply chain strategy providers, taking charge where the individual supply chain stakeholder is not taking (enough) charge.

Why orchestrate?

The concept of orchestration implies that successful supply chains, or supply networks, are governed by an aggregate player—a ‘‘hub’’ firm—whose role is to provide the required services and assume control of a part of the supply network, and consequently, there is

an undeniable trend that 3PLs have become brokers organizing supply chain networks. Through this process of organizing networks, sharing information, managing assets, and reducing inventory, 3PLs facilitate SCM best practices and become an orchestrator.

Not companies, but supply chains compete, said Martin Christopher, but in order to compete, one needs a good 3PL, obviously, and a 3PL that can provide flexibility, as described in Naim et al. (2010).

How orchestrate?

What defines an orchestrator? Well, four things, according to the authors:

As 3PLs work simultaneously with multiple supply chain partners, they can standardize data and processes across firms and provide supply chain visibility beyond the individual firm. In addition to providing standardization and visibility, they can be neutral arbitrators between entities because they are typically unbiased third-parties. 3PLs can serve as change agents, especially in the case of full outsourcing. Finally, because 3PLs can see opportunities for improvement through standardization and visibility and pursue them without being perceived as driving their own agenda, they can often facilitate collaboration much more effectively than a customer, supplier, or competitor within the supply chain.

Therefore, what makes a 3PL an orchestrator is the degree to which he can assist a company with standardization, visibility, neutral arbitration, and collaboration. The model is formulated in the figure below:

Based on their model, the authors develop seven propositions as to how the 3PL can fill the role as orchestrator:

Proposition 1: The higher the degree of standardization provided by the 3PL, the greater the value creation orchestrated by the 3PL.

Why? Because standardized processes enable smooth hand-off and flow of goods among all members of the supply chain.

Proposition 2: Standardization will positively impact visibility of the 3PL.

Why? Because without standardization, visibility would not be possible, since standard data and processes enable visibility to opportunities for load consolidation, improved asset utilization

Proposition 3: The higher the degree of visibility provided by the 3PL, the greater the value creation orchestrated by the 3PL.

Why? Because 3PL firms have the ability to see across multiple firms and echelons of the supply chain and orchestrate them as a whole for the good of all.

Proposition 4: Visibility will positively impact neutral arbitration by the 3PL.

Why? Because by having full visibility of the chain 3PL firms can see conflicting issues and barriers from the outside and instigate changes without being perceived as pursuing their own or some competitor’s agenda.

Proposition 5: The greater the degree of neutral arbitration provided by the 3PL, the greater the value creation orchestrated by the 3PL.

Why? Because companies may be more willing to listen to the advice of a neutral 3PL who has a wide range of experience and provides a clear benchmark in their particular industry.

Proposition 6: Neutral arbitration will positively impact collaboration of the 3PL.

Why? As a neutral arbitrator with visibility of information from multiple parties in the supply chain, 3PL companies can play a unique facilitating role in collaboration, similar to proposition 4.

Proposition 7: The greater the degree of collaboration provided by the 3PL, the greater the value creation orchestrated by the 3PL.

Why? Because 3PLs are uniquely positioned to find opportunities where they can encourage firms to share resources and combine knowledge, skills, and physical assets to create strategic advantage and enhance profits.

Conclusion

This paper is solid academic craftmanship, albeit “craftmanship” is perhaps the wrong word here. It is interesting to see how the mundane side of day-to-day supply chain operations, aka 3PL, is gaining attention as a crucial contributor to the overall value creation. There haven’t been too many papers on this, albeit some have lamented the unfortunate separation of supply chain management and logistics. The role of 3PLs is undoubtedly becoming increasingly important, not only as a supply chain facilitator, but also as a supply chain risk mitigator, something I have barely begun to research myself, and which this paper has inspired me to continue investigating. Perhaps logistics is what drives supply chains, and it is logistics that we should focus on, and not the other way around, where supply chain management overshadows logistics?

Reference

Zacharia, Z., Sanders, N., & Nix, N. (2011). The Emerging Role of the Third-Party Logistics Provider (3PL) as an Orchestrator Journal of Business Logistics, 32 (1), 40-54 DOI: 10.1111/j.2158-1592.2011.01004.x

Author links

- linkedin.com: Zach Zacharia

- linkedin.com: Nada R Sanders

- researchgate.net: Nancy W Nix