Are you are taking radically different actions than your peers when it comes to supply chain risk management? If so, Marsh Consulting thinks you are an innovator and blazing the trail for others to follow. At least, that’s what they say in their report Stemming the Rising Tide of Supply Chain Risks: How Risk Managers’ Roles and Responsibilities Are Changing. Penned by Beth Enslow and written in 2008 and well before the global financial downturn had companies think of anything but supply chain risk, this study of 110 North American risk managers by Marsh in collaboration with Risk Insurance magazine found that only 35 percent considered their companies to be “moderately effective” at managing supply chain risk, not a very uplifting figure, I must say. Having said that, the report clearly shows what “the innovators” do differently and how they have managed to “rein in” their supply chain risks, as the report says.

Are you are taking radically different actions than your peers when it comes to supply chain risk management? If so, Marsh Consulting thinks you are an innovator and blazing the trail for others to follow. At least, that’s what they say in their report Stemming the Rising Tide of Supply Chain Risks: How Risk Managers’ Roles and Responsibilities Are Changing. Penned by Beth Enslow and written in 2008 and well before the global financial downturn had companies think of anything but supply chain risk, this study of 110 North American risk managers by Marsh in collaboration with Risk Insurance magazine found that only 35 percent considered their companies to be “moderately effective” at managing supply chain risk, not a very uplifting figure, I must say. Having said that, the report clearly shows what “the innovators” do differently and how they have managed to “rein in” their supply chain risks, as the report says.

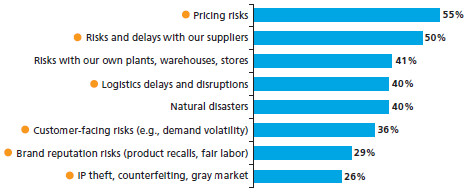

What are the Top Supply Chain Risks?

The Marsh report is based on a survey of 110 risk management professionals conducted in January and February 2008. The study results, so the report, are remarkably consistent across industry and company size, suggesting that there are common supply chain risk pain points and best practices across the risk management profession. The list of what were the top concerns in supply chain risk management in 2008 is quite interesting:

According to one of the respondents, “The most concerning risk issues, he says, are labor issues, raw material costs, political and regulatory climates, import/export restrictions, and risks involving shifting production from plant to plant or country to country.”

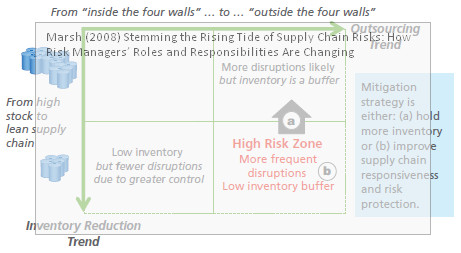

Why have Supply Chain risks increased?

According to Marsh, Although supply chain risks have always been present, they are being exacerbated by two forces: the move to leaner supply chains holding less inventory and the move to increased outsourcing.

This reminds me of my post on Lean logistics means risky logistics that I wrote two years ago. The report further notes that

more volatile supply chains also create margin risks for enterprises. Many companies find their expected sourcing savings from lower-cost areas to be significantly eroded by unanticipated supply chain volatility, leading to increased safety stock requirements, expensive transportation expediting costs, more quality control expenditures.

Indeed, while outsourcing foes have its benefits, supply chain risk cannot be outsourced, as Jack Barry wrote in 2004.

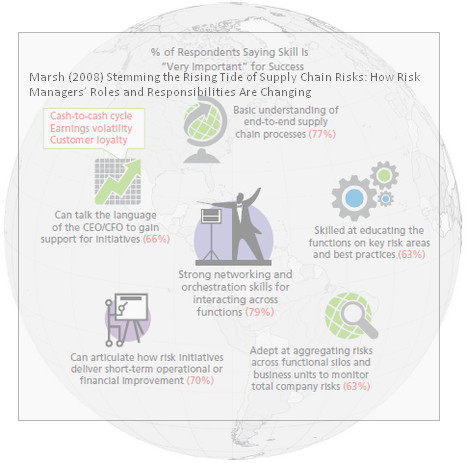

What are important success criteria in battling supply chain risks?

Finally, the report highlights the importance of the role of the risk manager and lists the skills a risk manager must possess in order to succeed,

So, how can a company improve its risk management? It can:

- Have the risk manager take a strategic role in mobilizing the company against both insurable and uninsurable supply chain risks

- Implement supply chain risk management processes that are consistent across the enterprise and are designed end-to-end, including direct suppliers, critical raw material suppliers, and logistics partners.

- Embed risk management activities and responsibilities into existing supply chain processes and functions.

- Use a cross-functional team to manage supply chain risks.

Nothing revolutionary new, but nonetheless, an important reminder that supply chain risk management best practices are not very sophisticated and not something only major corporations can afford.

Conclusion

As mentioned, this report was written before the financial downturn, and in my opinion, in the three years since then it has not lost much of its timeliness and is as up to date now as it was then.

Read more: Marsh’ Risk Insights

FYI, Marsh is a leading insurance broker and risk adviser and has a dedicated website on all sorts of risk issues in business: Marsh Risk issues

Reference

Enslow, B. (2008) Stemming the Rising Tide of Supply Chain Risks: How Risk Managers’ Roles and Responsibilities Are Changing. Marsh Inc.

Download the report

Related link

- marsh.com: Insights in Supply Chain Risk