Material breakages and damages are not unknown incidents in supply chains, but material damage and occupational accidents are nonetheless little understood elements of the overall supply chain. What is perhaps even lesser known is how occupational hazards and work environment safety link up with material damage. That is what Pia Perttula investigates in Safety of a logistics chain: a case study. Here here he looks at the paper industry in Finland and the occupational accidents that occur in the supply chain from the paper mill to the harbor of arrival. Interestingly, the paper finds that that workers handling the material were not aware of the extent of the damage, nor the monetary value it represented, indicating that material damage is a whole supply chain issue, and not a matter of the individual supply chain parties only.

Material breakages and damages are not unknown incidents in supply chains, but material damage and occupational accidents are nonetheless little understood elements of the overall supply chain. What is perhaps even lesser known is how occupational hazards and work environment safety link up with material damage. That is what Pia Perttula investigates in Safety of a logistics chain: a case study. Here here he looks at the paper industry in Finland and the occupational accidents that occur in the supply chain from the paper mill to the harbor of arrival. Interestingly, the paper finds that that workers handling the material were not aware of the extent of the damage, nor the monetary value it represented, indicating that material damage is a whole supply chain issue, and not a matter of the individual supply chain parties only.

Material damage and occupational accidents

Finland is one of the world’s major paper producers and the transportation of wood logs and paper reels is an important part of all logistical activities. Accidents involving paper trucks are not uncommon in Finland, or for that matter, paper reels falling off at various stages in the supply chain.

The costs of occupational accidents in a company can be significant, depending on the type of accident, sick leave payments, and how the accident affects, for instance, the production process and the scope of administration and information activities, and materials damage. Accidents entail costs and have a negative effect on the health of workers, the enterprise and workplace atmosphere. In addition to the extra salary costs, accidents:

– lower the level of production and services

– lower quality

– delay deliveries

– cause overtime

– necessitate substitute workers

– cause additional administrative work

– require compensation for damage

Clearly, and I have to agree with the author on this, there is an urgency in the task of examining occupational accidents in logistics and doing research for preventing them.

Case study

The material is based on data from a case study about the transportation of paper in Finland:

Six companies were involved in the operation of the paper logistics chain studied: storage of the paper mill, transportation by railway, outbound harbor operations, vessel, inbound harbor, and truck-trailer delivery. The volume moved was 77,000 tons of paper per year. The process began at the paper mill in central Finland and ended at a harbor in Germany. At the paper mill, the paper reels were loaded by fork-lifts onto the railway carriages. At the Finnish harbor, the reels were unloaded from the railway carriage and stored until they were loaded onto the vessel. The paper was transported onward from the German harbor by trailers to the customers.

While the study is limited in the sense that it only covers one type of product, the many modes of transport and loading/unloading operations do contain many risk sources and risk drivers, and are thus a fruitful area for research.

Occupational accidents cost money

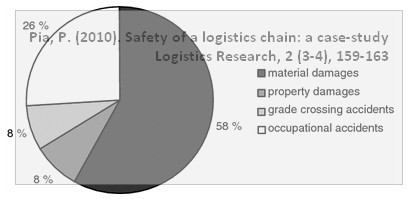

The study found that while material damages make up 58% of unwanted events in the supply chain, occupational accidents account for as much as 26%.

Converted to monetary value, this represented 1% of the total logistical costs, which may seem insignificant at first, but it is certainly not a negligible cost. Besides, dangerous work environments will sooner or later turn into reputation risk, or worse, turn out to be the precursor or catalyst for a major crisis in one of the parties involved in the supply chain. And shouldn’t a safe work enviroment be part of corporate social responsibility anyway?

Does material damage happen where you expect it?

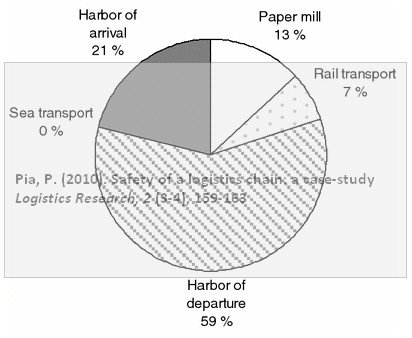

Interestingly, the study finds that most material damages happen in the harbor of departure.

The implications are far-reaching:

The damage to a paper reel usually happens quietly. It is not easily noticed. In the chain studied, most of the materials damage occurred at the harbor. However, most of the damage was not noticed until the paper reels reached the customer. Transporting damaged reels costs as much as transporting undamaged reels, as the logistic costs are the same. The later a material damage is recognized in the logistic chain, the more unnecessary logistic costs have arisen, and the whole transportation process is in vain if a paper reel is damaged in the paper mill but the damage is not noticed until in the harbor of arrival. A large proportion of the damaged reels, therefore, was transported to the customer. If the damage is noticed in the country of origin, the material can be returned to the mill and reused. Most of the damaged reels were repairable. Both harbors had repairing centers, which fixed the reels if the damage was not too great. The damaged reel could then be reused. However, this involved a great deal of work: the reels have to be transported to the repairing center and stored there for checking. After it is repaired, the reel needs a new label with the new information. The repaired reel can either be simply added to the original order, or a new order can be made and the reel stored until dispatch. This process also requires management resources.

End result: One small damage can have very costly consequences.

Damages and accidents

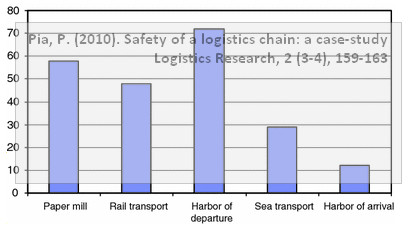

The study finds that not only do most material damages happen in the harbor of departure, but so do most occupational accidents also:

Interesting. Obviously, the harbor of departure is a trouble spot. Strangely, the accident rate in the harbor of arrival is much lower, albeit the handling of the reels when unloading should not differ too much from the handling when loading…or is it? Are German workers so much more concerned with safety than Finnish workers?

Conclusion

This a limited study looking at a specific product in a specific supply chain. That said, it is the only study that links occupational accidents with material damage and the only study that mentions occupational hazards as a risk in the supply chain. The study also highlights the importance of realizing material damage as soon as possible in the supply chain, to prevent an accumulation of costs further downstream, thus showing the importance of cooperation and collaboration in the overall supply chain.

Reference

Pia, P. (2010). Safety of a logistics chain: a case-study Logistics Research, 2 (3-4), 159-163 DOI: 10.1007/s12159-010-0037-2

Author link

- ttl.fi: Pia Perttula

- linkedin.com: Pia Perttula

(While the paper lists the author as Perttula Pia, I believe they may have mixed up the first and last name)