In a previous paper, back in 2004, I discussed the issue of Flexibility and robustness as options to reduce risk and uncertainty. Since then a new term has emerged: resilience, and today I would like to compare these three terms. Robustness is the ability to accommodate any uncertain future events or unexpected developments such that the initially desired future state can still be reached. Flexibility is the ability to defer, abandon, expand, or contract any investment towards the desired goal. Resilience is the ability of a system to return to its original state or move to a new desirable state after being disturbed.

In a previous paper, back in 2004, I discussed the issue of Flexibility and robustness as options to reduce risk and uncertainty. Since then a new term has emerged: resilience, and today I would like to compare these three terms. Robustness is the ability to accommodate any uncertain future events or unexpected developments such that the initially desired future state can still be reached. Flexibility is the ability to defer, abandon, expand, or contract any investment towards the desired goal. Resilience is the ability of a system to return to its original state or move to a new desirable state after being disturbed.

Note:

This post is based on my previous work in

husdal.com: Flexibility and Robustness (2004)

The framework in this post has been further refined in later posts:

husdal.com: Robustness, resilience, flexibility and agility (2009)

husdal.com: Robust, Flexible, Agile, Resilient. What does it mean? (2015)

Flexibility and robustness are two sides of the same coin, yet at the same time two distinctively different animals. Flexibility is the inherent capability to modify a current direction to accommodate and successfully adapt to changes in the environment, whereas robustness refers to the ability to endure such changes without adapting.Resilience, in essence, is the ability to survive these changes despite severe impact.

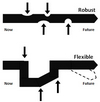

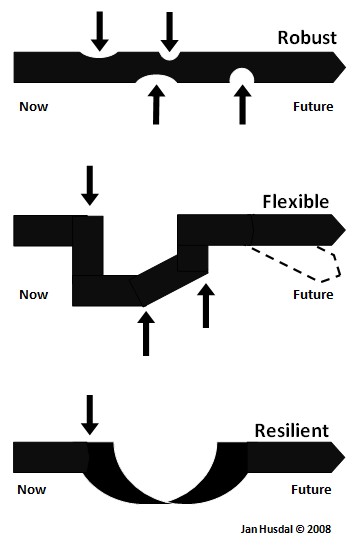

Let me explain the figure below. The thick line symbolizes the supply chain, going from its current state “now” to a future state “future”. The thinner arrows indicate events that may or may not disrupt the supply chain. The thickness of the supply chain arrow indicates how seriously impacted the supply is by these events.

A robust supply chain stays on course, so to speak. Yes, there are impacts, but they do not severely hamper the flow of the supply chain or supply network. Example: having a redundant production line, just in case.

A flexible supply chain is able to accommodate disruptions by changing its course and even the target, the flow itself (the throughput) is not impacted. Example: switching suppliers or re-designing a product.

A resilient supply chain is impacted, but it is able to come back to where it was. This may often be the case after disruptions due to natural disasters or after loosing the only single-source supplier.

Although these three terms are distinctively different it is practically impossible to draw a clear line between them as far as supply chains are concerned, saying that a supply chain is either this or that. Which strategy that works best would depend not only on the supply chain in question as a whole, but also which part of the supply chain that may be vulnerable. A best-practice supply chain would in fact encompass all three, making it robust, flexible and resilient at the same time.

For a fuller discussion of robustness, flexibility, resilience and agility, you may be interested in reading an updated version of this post, which also includes literature references: De-confusing robustness, resilience, flexibility and agility

Related

- husdal.com: Robustness and flexibility as options to reduce uncertainty (2004)

- husdal.com: De-confusing robustness, resilience, flexibility and agility (2009)

- husdal.com: Robust, Flexible, Agile, Resilient. What does it mean? (2015)