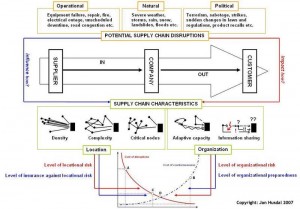

This is a brief description of a model I developed for supply chain risk and vulnerability, with risks and disruptions on one side and the vulnerability and impacts on the other side: A typical supply chain consists of a company with incoming raw materials from an upstream supplier and outgoing products to a downstream customer, and is characterized by its locational and organizational design. There are many potential disruptions to a supply chain that may or that may not influence locational decisions. And finally, the impact and severity of disruptions depends on both locational vulnerability and organizational adaptability

This is a brief description of a model I developed for supply chain risk and vulnerability, with risks and disruptions on one side and the vulnerability and impacts on the other side: A typical supply chain consists of a company with incoming raw materials from an upstream supplier and outgoing products to a downstream customer, and is characterized by its locational and organizational design. There are many potential disruptions to a supply chain that may or that may not influence locational decisions. And finally, the impact and severity of disruptions depends on both locational vulnerability and organizational adaptability

Potential disruptions to a supply chain can be categorized as operational, natural and political events. Operational events are events that occur in the day-to-day operation, such as equipment failure, repair, fire, electrical outage, unscheduled downtime. These events are potentially controllable or foreseeable events. Natural events are events caused by natural hazards, such as severe weather, storms, rain, snow, landslides, floods etc. These events are beyond the scope of control and are seldom foreseeable. Political events are events such as terrorism, sabotage, strikes, sudden changes in laws and regulations, product recalls etc. These too are usually beyond the scope of control and not foreseeable.

In terms of location, suppliers (or customers) can be clustered together in a dense formation or not, the supply chain may be complex with or without interdependencies, or it may be characterized by critical nodes, through which every item in the chain has to pass. The organizations within the supply chain may or may not be equipped with an adaptive capacity, and in addition, there may or may not be established a protocol of system wide sharing of information on events within the chain.

A disruption has a cost associated with it, but preparing for potential disruptions by investing in countermeasures may lower the cost of disruptions. However, there is the danger of “over insuring” against disruptions.

The level of locational risk the company is facing or willing to face determines the costs the company will incur, should a disruption occurs. The company can hedge against this locational risk by investing in organizational preparedness, and leave locational matters as they are, or the company can seek to reduce the level of locational exposure, without implementing organizational measures, or it can do a combination of both.

Likewise, the organizational preparedness, or rather un-preparedness, is a measure of the level of organizational risk the company is willing to take. However, the better a company is prepared for disruptions, the less it may be impacted by locational risk.

You can find more on this concept in my 2009 presentation for the TRB on sparse transportation networks, see link below.