The book Strategies for Building Successful Global Businesses

The book Strategies for Building Successful Global Businesses, by the INSEAD-Wharton Alliance on Globalizing, contains 6 articles on managing risk and uncertainty. Today I will look at one of these articles that deserves further mentioning: Managing risk in global supply chains by Paul W. Kleindorfer and Luk N. van Wassenhove.

The article starts off with a brief recap of the development of supply chain management, and why supply chain risk management has become increasingly important. A supply chain is essentially a network consisting of suppliers, manufacturers, distributors, retailers and customers. The network supports three flows, requiring careful design and close coordination, if risk is to be avoided:

- Material flows

- Information flows

- Financial flows

These flows are sometimes referred to as the “3Bs” of supply chain management:

- Boxes

- Bytes

- Bucks

Traditionally, the boxes have received the most attention, but all three flows are equally important, since disruptions can occur in any of them, thus halting the supply chain.

The flows, in turn, are supported by three pillars:

- Processes

- Organizational structure

- Technologies

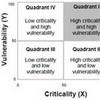

Supply chain risk management must address both the flows and the pillars the floes rest on.In essence, the article differs between two types of risk:

- Supply-demand coordination risk

- Disruption risk

In battling these risks companies normally draw upon three approaches:

- Supply chain design

- Contracting

- Risk management systems

Supply-demand coordination risks can be addressed using

- Three dimensional concurrent engineering

- Dynamic supply-demand balancing

- Closed loop supply chains

- B2B exchanges

In terms of managing disruption risk, the article looks at

- Purposeful triggers

- Accidental triggers

So far so good, but this is where the article suddenly drops in usefulness. Whereas supply-demand coordination is dealt with in detail, disruption risk only receive a cursory review. Terrorist attacks or changes in regulations are seen as examples of purposeful triggers, and accidental triggers are near misses or on-site accidents like fires or chemical spills. Admittedly, these risk should be of major concern to any company, however, I fail to to see their significance as disruption risks. On the other hand, the article does suggest multi-level exercises at each link in the supply chain as a method to uncover vulnerabilities and to find ways to mitigate or respond to these vulnerabilities. In addition, the article also makes a point in underscoring that supply chain design decisions should not be done purely on the basis of cost and revenue determinants.

In conclusion, and this is where I agree with the authors, the basic challenge is finding the right balance between the leanness and the robustness of supply chains, and thus increasing the overall returns in global supply chains.

Reference

Kleindorfer, P. R. and van Wassenhove, L.N. (2004) Managing Risk in Global Supply Chains. In: The INSEAD-Wharton Alliance on Globalizing – Strategies for Building Sucessful Global Businesses. Eds. Gatignon, H. and Kimberly, J.R., pp. 288-305. Cambridge University Press.

Author links

- upenn.edu: Paul Kleindorfer

- insead.edu: Luk van Wassenhove

Related

- husdal.com: What’s so special about Paul Kleindorfer?

- husdal.com: Global Supply Chain Risk Management Strategies

- husdal.com: Global Supply Chain Risk Management

- husdal.com: Book Review: Handbook of Global Supply Chain Management

- husdal.com: Strategies for managing risk in multinational corporations