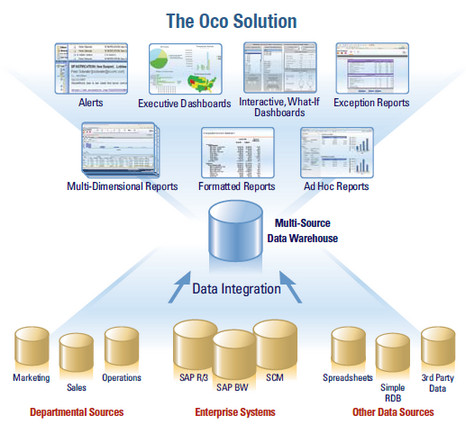

In my postings on supply chain risk and supply chain disruption, there is one thing that I have overlooked: Business Intelligence. Well, not overlooked, maybe, but underestimated, because Business Intelligence is a key component in mitigating supply chain risk and also a key component in recovering critical information after a supply chain disruption. Now, there are two ways business intelligence can be managed: in-house and out-house or on-demand. In this post I will look at at on-demand complementary business intelligence, using the solution provided by Oco as an example.

Oco

The business idea of Oco is to take any amount of data from any system in any location, integrate and organize it in powerful, easy-to-use reporting and analytics, thus providing essential business visibility in design and production, sales and marketing, and customer behavior. This information, also termed business intelligence, is what drives business decisions.

Seeing what is wrong (or not wrong)

How important supply chain visibility is in foreseeing and handling supply chain disruptions is greatly underscored in the article by Craighead et al. on The Severity of Supply Chain Disruptions: Design Characteristics and Mitigation Capabilities, which I have reviewed earlier. The article contends that a supply chain disruption is less likely to be severe if there is a capability to quickly detect and disseminate information about the event and thus respond and correct in a proactive or reactive manner. However, correctly detecting, correctly disseminating and correctly responding requires correct intelligence data. Besides in-house solutions, a 2nd way to achieve this is complementary business intelligence and software as a service (SaaS).

Complementary BI

Software as a service (SaaS) is a model of software deployment where an application is hosted as a service provided to customers across the Internet. By eliminating the need to install and run the application on the customer’s own computer, SaaS alleviates the customer’s burden of software maintenance, ongoing operation, and support [Wikipedia]. SaaS is typically thought of as a low-cost way for businesses to obtain the same benefits of commercially licensed, internally operated software without the associated complexity and high initial cost. Using the service become a continuous expense (or a on-demand expense), rather than a single expense at time of purchase. The Oco website has More info on Complementary BI, where you can Download a Free White Paper on Complementary BI.

Low cost, so what?

Although SaaS may appear to be a low-cost cheapskate solution, in fact, it is not. First of all, it allows you to focus you efforts (and dollars) where they matter, and a third-party solution is often more thought through, more updated and easier improved than an in-house solution. Being deployed via the Internet it is also readily available to all parts of the organization, even in a global setting. This of course requires a working Internet connection at all times, but that is probably easier to achieve for the IT department than Internet AND running the software in-house.

SaaS and Business Continuity

The second reason why Complementary BI or SaaS is better than in-house solutions is when you look at it from a business continuity perspective. Should disaster strike, your information is still readily available, with full access to important supply chain areas such as

- vendor scorecards

- purchasing

- inventory

- operations & quality management

- service performance

- asset management

The Oco website shows you just how versatile complementary BI can be for supply chain managment.

Why SaaS and Complementary BI?

If you’re running a small nuts and bolts company, I would definitely consider an out-house solution over an in-house solution. Simply because it’s cheaper, and you will probably get more (let alone more useful) business intelligence from a 3rd-party, tested and tried, software solution than trying to develop a makeshift application yourself.

By applying economies of scale to the operation of applications, a service provider can offer better, cheaper, more reliable applications than companies can themselves. But even if, or particulary if you’re a large corporation, SaaS is worth considering.

Conclusion

Having access to the correct business intelligence is essential for detecting any anomalies in your supply chain, and sunsequently taking proactive measures. That is how Nokia discovered that something was amiss after the fire at the Philips plant in Albuquerque in 2001, albeit they probably had never heard of and did not use SaaS or Complementary BI at that time. Complementary BI and SaaS can be a low-cost insurance against not seeing where or when things go wrong.

More information

Before you start with the services rendered by Oco (or any other company that provides SaaS), make sure you read up on the subject, e.g. Wikipedia is also a great source for info on SaaS. Personally, I think SaaS is here to stay. One of the most compelling reasons for developing SaaS applications is the opportunity to implement alternative pricing models that focus on establishing and maintaining recurring revenue streams.

Related

- husdal.com: Web Conferencing – a tool for SCM?