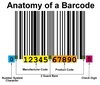

Have you ever thought about how barcodes are a major factor in performance of supply chains? As we all know, the devil is in the details. And a supply chain is usually not a simple chain of one supplier, one manufacturer and one retailer, but a highly interwoven network of many players. How can you keep track of all the items flowing through the chain..ehrm, network? Before, we had manual hand-written lists, then came computerized lists (but still manual). Now we have barcodes.

Have you ever thought about how barcodes are a major factor in performance of supply chains? As we all know, the devil is in the details. And a supply chain is usually not a simple chain of one supplier, one manufacturer and one retailer, but a highly interwoven network of many players. How can you keep track of all the items flowing through the chain..ehrm, network? Before, we had manual hand-written lists, then came computerized lists (but still manual). Now we have barcodes.

Inventory Control

Barcodes are undoubtedly an integral part of today’s modern business life. One of the most prominent uses of barcodes can be found in Inventory Control. Modern inventory control systems rely upon barcodes, and potentially RFID tags, to provide automatic identification of inventory objects. You will have probably seen you local store attendant using barcode scanners to keep track of out-of-stock items on the store shelves. For an overview of types of barcode scanners I decided to use a company called Wasp Barcode Technologies as an illustration: Examples of Barcode Scanners.

Barcodes are undoubtedly an integral part of today’s modern business life. One of the most prominent uses of barcodes can be found in Inventory Control. Modern inventory control systems rely upon barcodes, and potentially RFID tags, to provide automatic identification of inventory objects. You will have probably seen you local store attendant using barcode scanners to keep track of out-of-stock items on the store shelves. For an overview of types of barcode scanners I decided to use a company called Wasp Barcode Technologies as an illustration: Examples of Barcode Scanners.

According to Wikipedia, an inventory control system is

… an integrated package of software and hardware used in warehouse operations, and elsewhere, to monitor the quantity, location and status of inventory as well as the related shipping, receiving, picking and putaway processes.

Using the scanner and inventory control software it is easy to check where any item is at any given moment. Historically, complex inventory tracking systems were designed for major corporations running distribution centers and warehouses that were automated with barcodes. Nonetheless, even small enterprises can benefit from tracking their inventory and assets. And not only “businesses”, even many hospitals use barcodes for inventory control. Barcodes can even be used for employee tracking and “control” and linked up to a time attendance software. I’m glad my company hasn’t installed one of these things…yet.

Manual or computerized inventory control?

In today’s business environment, even small and mid-sized businesses have come to rely on computerized inventory management systems. Certainly, there are plenty of small retail outlets, manufacturers, and other businesses that continue to rely on manual means of inventory tracking. Indeed, for some small businesses, like convenience stores, shoe stores, or nurseries, purchase of an electronic inventory tracking system might constitute a wasteful use of financial resources. But for other firms operating in industries that feature high volume turnover of raw materials and/or finished products, computerized tracking systems have emerged as a key component of business strategies aimed at increasing productivity and maintaining competitiveness.

Links

- wikipedia – Inventory Control System

- answers.com – Inventory Control System