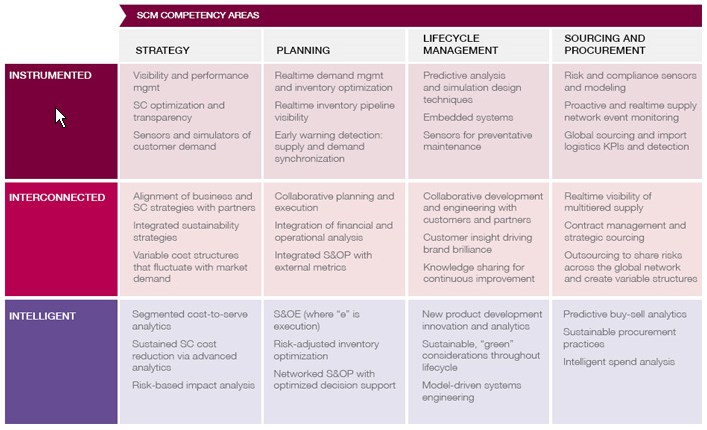

A recent report by IBM, referenced by Supply Chain Digest in IBM Lays Out its Vision for the Supply Chain of the Future, makes a compelling argument for how future supply chains should be: instrumented, interconnected and intelligent. The article features an interesting table, where these three characteristics are linked to SCM competencies and how they can be implemented.

A recent report by IBM, referenced by Supply Chain Digest in IBM Lays Out its Vision for the Supply Chain of the Future, makes a compelling argument for how future supply chains should be: instrumented, interconnected and intelligent. The article features an interesting table, where these three characteristics are linked to SCM competencies and how they can be implemented.

Supply Chain Evolution

In the past, it was all about operations, hence instrumentation was the way forward. Recently, with globalization, interconnections arose as the new keyword. Today, pointing towards the future that lies ahead, both must come together as intelligence. That is the new and smart supply chain..

According to SC Digest, the report says that

Globalization and growing supply chain interdependence have introduced a heightened level of volatility and vulnerability that is unlikely to subside. Uncertainty has become the norm. This new environment demands a different kind of supply chain – a much smarter one.

Competencies and Characteristics

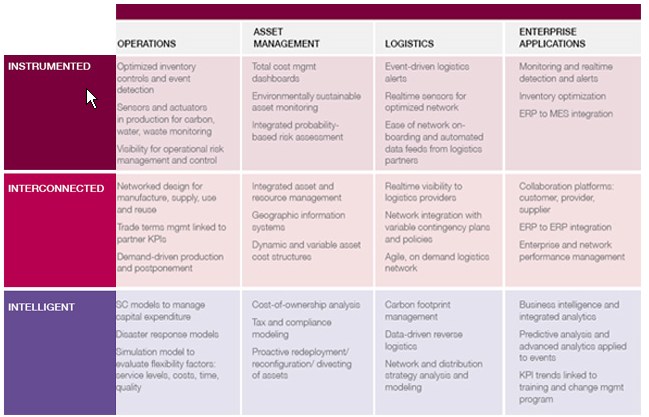

The figures in the article on SC Digest is apparently taken straight out of the IBM report, summarizing what the impact will be of moving to a supply chain of the future, and how

Characteristics

- instrumented

- interconnected

- intelligent

can be linked to

Competencies

- Strategy

- Planning

- Lifecycle Management

- Sourcing and Procurement

- Operations

- Asset Management

- Logistics

- Enterprise Applications

like this

Smart Risk Management

Looking closer look at the competencies-characteristics matrix and how it relates to supply chain risk and supply chain vulnerability, I can see that most if not all implications in the figures above have a direct bearing on risk and vulnerability. Some even mention the word “risk”, as in

- intelligent strategy: risk-based impact analysis

- intelligent planning: risk-adjusted inventory optimization

- interconnected sourcing: outsourcing to share risks across the global network and to create variable structures

- instrumented operations: visibility for operational risk and control

- instrumented asset management: integrated probability-based asset management

- interconnected logistics: network integration with variable contingency plans

Even though risk is not verbatim mentioned in all implications in the matrix, there is a clear link towards reducing supply chain risk, such as in

- instrumented enterprise applications:monitoring and realtime detection and alerts

- intelligent operations: disaster response models

- instrumented planning: early warning detection – synchronized demand and supply planning

- interconnected strategy: variable cost structures that fluctuate with market demand

Conclusion

IBM says, and I fully agree, that when it comes to supply chain visibility, increasingly

the issues will not be about having too little information, but rather too much. Smarter supply chains, however, will use intelligent modeling, analytic and simulation capabilities to make sense of it all

That is why the supply chain of the future needs to be “smart”.

Link

SC Digest – IBM Lays Out its Vision for the Supply Chain of the Future