No, it’s not that supply chain risk is a forgotten discipline, it’ is well and alive an kicking, it’s just that I forgot to write my post on the chapter on supply chain risk in Martin Christopher’s book, which I said I would do in my review of his book Logistics and Supply Chain Management. I remembered my promise while preparing my book chapter on Risks in Virtual Enterprise Networks, because I used Christopher when discussing those risks. Below are some of the highlights from the chapter on supply chain risk in Christopher’s book, and some personal reflections.

No, it’s not that supply chain risk is a forgotten discipline, it’ is well and alive an kicking, it’s just that I forgot to write my post on the chapter on supply chain risk in Martin Christopher’s book, which I said I would do in my review of his book Logistics and Supply Chain Management. I remembered my promise while preparing my book chapter on Risks in Virtual Enterprise Networks, because I used Christopher when discussing those risks. Below are some of the highlights from the chapter on supply chain risk in Christopher’s book, and some personal reflections.

Supply Chain Risk explained

Risk reflects both the range of possible outcomes and the probabilities for each of the outcomes. Christopher advocates establishing a supply chain risk profile, with the purpose to establish where the greatest vulnerabilities lie and where the “greatest” risks are, based on the view that risk is the product of probability and impact.

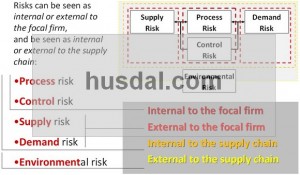

He distinguishes between 3 risk perspectives and 5 risk types, namely 1) Internal to the focal firm: a) Process risk and b) Control risk, 2) External to the focal firm: c) Supply risk and d) Demand risk, and 3) External to the supply chain: e) Environmental risks. Process risks relate to operations and manufacturing, while control risks relate to rules and systems governing the organization. Supply risks relate to the upstream flow of incoming supplies, while demand risks relate to downstream disruptions in outgoing product flows or incoming financial flows. Environmental risks relate to the outside world, regulatory or political changes, natural hazards or other disasters. Actually, there is another, fourth, perspective, where both firm-internal and firm-external risks are contained: Internal to the supply chain (Process, Control, Supply and Demand).

Supply Chain Vulnerability

Christopher defines vulnerability as “an exposure to serious disturbance”, arising from internal as well as external risk, caused by current trends in supply chain mangement:

- The trend towards just in time and lean practices

>>> efficiency rather than effectiveness - The trend towards reducing costs

>>> globalization, more complex and longer supply chains - The trend towards economies of scale

>>> centralized distribution and manufacturing

>>> lower costs, but also less flexibility - The trend towards outsourcing of non-core business activities

>>> loss of control when it is most needed - The trend towards consolidation of suppliers

>>> increased potential for wider impacts of disruptions

Strategies for mitigation

Citing from an article in Harvard Business Review, he lists six steps for mapping the risk profile and developing strategies:

- Prioritize earnings drivers

- Identify critical infrastructure that affect the earnings drivers

- Locate vulnerabilities in the critical infrastructure

- Model scenarios for the vulnerabilities

- Develop responses to the scenarios

- Monitor, detect and respond to potential disruptions as soon as possible

He then suggests a very simple and straightforward framework for managing supply chain risk

- Understand the supply chain

- view it from end to end, from supplier to end customer.

- Improve the supply chain

- can you simplify and reduce complexity and variability?

- Identify critical paths

- what are the bottlenecks and key nodes/links?

- Manage the critical paths

- make contingency plans.

- Establish a supply chain continuity team

- make it cross-functional

- Allow network visibility

- don’t be afraid to share information.

- Work with suppliers and customers

- are your suppliers and customers aware of their own vulnerabilities?

- are your suppliers and customers aware of your own vulnerabilities?

I think that particularly the last two bullet points may raise some eyebrows with supply chain risk managers, who would rather like to keep this information privy to the company, and not share it with the outside world. The benfits of doing this though, outweigh the disadvantages, as i see it

SCOR

On a side note, it is noteworthy that the Supply Chain Council (SCC) now has implemented supply chain risk into their SCOR model The SCOR reference model is a widely accepted framework for evaluating and comparing supply chain activities and their performance, and uses the same four perspectives : 1) Internal-facing, 2) Customer-facing and 3) Supply-facing and 4) Environment-facing. To me, this proves the validity of Christopher’s approach.

Reference

Christopher, M. (2005). Managing risk in the supply chain. In Logistics and Supply Chain Management (3rd ed., pp. 231-258). Harlow: Prentice Hall.

Author Link

- martin-christopher.info: Martin Christopher

amazon.com

- Buy this book: Logistics and Supply Chain Management

Related

- husdal.com: Book Review: Logistics and Supply Chain Management

The trend towards just in time and lean practices

>>> efficiency rather than effectiveness

The trend towards reducing costs

>>> globalization, more complex and longer supply chains

The trend towards economies of scale

>>> centralized distribution and manufacturing

>>> lower costs, but also less flexibility

The trend towards outsourcing of non-core business activities

>>> loss of control when it is most needed

The trend towards consolidation of suppliers

>>> increased potential for wider impacts of disruptions