A case of mistaken identity, or so I thought, but it’s not. There are in fact two separate articles, by the same authors, Manuj and Mentzer, with almost the same title, published the same year, 2008, in two different journals. Previously, I have reviewed Global Supply Chain Risk Management by Manuj and Mentzer, so when I first came across this second article in the reference list of a paper I simply thought it to be some “copy-and-paste”-work on the same topic, slightly tweaked and edited, and published in a different journal, just for the sake of boosting the authors’ publication record. How wrong of me. Global Supply Chain Risk Management Strategies by Ila Manuj and John T Mentzer IS indeed a different article, and it’s even better than the first one.

A case of mistaken identity, or so I thought, but it’s not. There are in fact two separate articles, by the same authors, Manuj and Mentzer, with almost the same title, published the same year, 2008, in two different journals. Previously, I have reviewed Global Supply Chain Risk Management by Manuj and Mentzer, so when I first came across this second article in the reference list of a paper I simply thought it to be some “copy-and-paste”-work on the same topic, slightly tweaked and edited, and published in a different journal, just for the sake of boosting the authors’ publication record. How wrong of me. Global Supply Chain Risk Management Strategies by Ila Manuj and John T Mentzer IS indeed a different article, and it’s even better than the first one.

Risk events

Building on their previous article, and based on in-depth interviews and a focus group meeting with senior supply chain executives, Manuj and Mentzer develop a list of risk events common in global supply chains:

- Currency

- Changes in exchange rates

- Transit time

- Variability of time spent in transit and port clearance

- Forecast

- Errors in prediction of demand leading to shortage or excess of stocks

- Quality

- Defective, damaged or wrong products or components, with problems and issues differing from site to site

- Safety

- Products causing safety hazards (often due to quality issues)

- Business disruption

- Supplier’s sudden inability to produce goods

- Survival

- Supplier suddenly going out of business/bankrupt

- Ownership of inventory, tools and processes

- Confusion or disputes over ownership of inventory or intellectual property

- Culture

- Inadequate knowledge about people, culture and language in foreign countries

- Opportunism

- The danger of suppliers or customers behaving opportunistically

- Oil price

- Fluctuations in oil price > logistics costs

Risk interactions

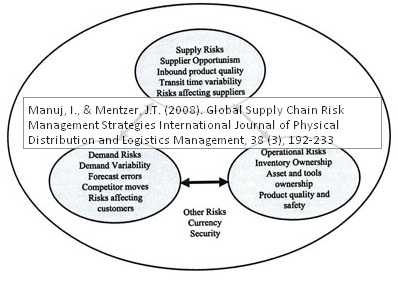

The figure left shows the interactions between the different types of risk, along with risk event examples.

This is similar to the division of risk applied in most of the supply chain risk literature: supply risk, demand risk and operational risk.

Risk management strategies

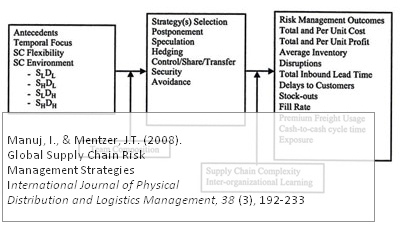

Based on their interviews, Manuj and Mentzer propose that three factors affect the selection of risk management strategies: temporal focus, supply chain flexibility and supply chain environment.

The links between the antecedents and the strategy selection are moderated by team composition. The selected strategy affects the risk management outcomes, and two other factors: supply chain complexity and interorganizational learning.

Nine propositions

In the figure above, under “SC environment”, the terms “S” and “D” refer to “Supply” and “Demand” risk, while “L” and “H” refer to “low” and “high”. This is used to develop a set of nine propositions:

- Supply chains facing S L D H and S H D H environments are more likely to adopt form postponement strategies than those facing S L D L and S H D L environments.

- Supply chains facing S L D L and S H D L environments are more likely to adopt a speculation strategy than supply chains facing S L D H and S H D H environments.

- Supply chains facing S H D L and S H D H environments are more likely to adopt hedging as compared to supply chains facing S L D L and S L D H environments.

- Supply chains facing S H D L environment are more likely to adopt backward integration, supply chains facing S L D H environments are more likely to adopt forward integration, and supply chains facing S H D H environments are more likely to adopt both backward and forward integration.

- All types of supply chains will increase the use of security strategies.

- Supply chains operating in all types of environment adopt avoidance strategies. Type 1 avoidance strategy is adopted when a supply chain has an option not to enter a high demand or supply risk environment. Type 2 avoidance strategy is adopted when a supply chain has no option but to enter a high demand and/or supply risk environment.

- Team composition affects the relationship between the antecedents and the strategy selected.

- Greater supply chain complexity lessens the relationship between supply chain risk strategies and risk-related outcomes.

- Greater inter-organizational learning strengthens the relationship between supply chain risk strategies and risk management outcomes.

Conclusion

One important implication from these propsitions is that although the literature certainly identifies several strategies for managing supply chain risks, it falls short in identifying when to use each strategy. This paper addresses this gap by identifying the most important antecedents to selection of risk management strategies and linking the antecedents to appropriate strategies.

Reference

Manuj, I., & Mentzer, J.T. (2008). Global Supply Chain Risk Management Strategies International Journal of Physical Distribution and Logistics Management, 38 (3), 192-233 DOI: 10.1108/09600030810866986

Author links

- wikipedia.org: John T Mentzer

- linkedin.com: Ila Manuj

Related

Manuj, I. and Mentzer, J.T. (2008) Global Supply Chain Risk Management. Journal of Business Logistics, 29(1), 133-155.