Today’s article is a continuation (or should it rightfully have been the precursor?) of an article I presented two weeks ago. Supply chain risk management and performance: A guiding framework for future development is written by Clare Brindley and Bob Ritchie. In so many ways it is very similar to An emergent framework for supply chain risk management and performance measurement, another article by Clare Brindley and Bob Ritchie that has previously been reviewed on this blog, but in so many other ways it is also very different.

Today’s article is a continuation (or should it rightfully have been the precursor?) of an article I presented two weeks ago. Supply chain risk management and performance: A guiding framework for future development is written by Clare Brindley and Bob Ritchie. In so many ways it is very similar to An emergent framework for supply chain risk management and performance measurement, another article by Clare Brindley and Bob Ritchie that has previously been reviewed on this blog, but in so many other ways it is also very different.

Same wine in two different bottles?

When I say that I am not sure which article comes first, it is because they are written by the same authors, published in the same year, deal with the same topic, published in two different journals, while at the same time taking similar, but different approaches. Nonetheless, each article stands out in its way and by its own right. The aims of this paper are to 1) explore the interaction between risk and performance in a supply chain context, 2) articulate the main strands of risk management within supply chain management, and 3) develop a framework encapsulating these strands and demonstrate its application in two empirical settings.

Risk

Ritchie and Brindley conclude that while there are many definitions of risk, what they have in common is related to

- the likelihood of occurrence of a particular event or outcome

- the consequences of the particular event or outcome occurring

- the causal pathway leading to the event

All three dimensions are important in risk management:

Risk management seeks to address all three dimensions of the risk construct by analyzing the sources, seeking to understand the forces that may drive a particular sequence of events and how these might be managed to improve the chances of positive outcomes in terms of performance and, by corollary, avoid negative consequences.

Supply chain risk management framework

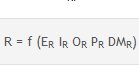

Building on earlier research, risk is defined as a function of environmental variables ER, industry variables IR, organizational strategy variables OR, problem specific variables P R, and decision-maker related variables DMR.

R = f (ER IR OR PR DMR)

This formulation provides the basis for their supply chain risk management framework, where each part contributes to and influences the next step:

- Risk Sources and Profile

- Risk & Performance Drivers

- Risk & performance Consequences

- Risk Management Responses

- Risk & Performance Outcomes

The supply chain risk management framework centers around these two questions:

Is it possible to prescribe risk management responses to address particular risk drivers or combinations of these? Will particular risk management responses reduce, ameliorate or ultimately eliminate exposure to particular risks and their consequences?

How do risk and performance drivers interact? Can risk reduction only effectively be achieved by the deterioration in some aspects of performance?

Risk sources

Ritchie and Brindley identify seven sources of risk

- Environment Characteristics

- Industry Characteristics

- Supply Chain Configuration

- Supply Chain Members

- Organizational Strategy

- Problem-specific Variables

- Decision-making Variables

The list implies that there can be no generally valid risk for all types of supply chains, but risks must be defined from within the context of the supply chain that is the subject of analysis. No supply chain is equal to any other supply chain, and each supply chain has its own and unique set of risks.

Risk performance and drivers

Ritchie and Brindley do not mention particular drivers, besides stating that

There are potentially an infinite number of factors exposing the business to undesirable consequences in terms of performance and risk.

and mentioning that the drivers need to be related to the sources, such that a generalization is practically impossible, and thus omitted in this paper. And admittedly, for the supply chain risk management framework, identifying all drivers is not important. After all, this is a framework, a framework that must be adapted to the individual situation, as indicated by the risk definition above.

Risk Performance Consequences, Risk Management Responses and Risk and Performance Outcomes

This is one of the shortcomings of the paper. Risk Performance Consequences, Risk Management Responses and Risk and Performance Outcomes are receive only a cursory treatment in the paper, and while discussed in the two cases at the end of the paper, the case discussion appears to deviate from the main framework for supply chain risk management. The discussion also highlights a framework mentioned in an early figure in the paper, namely the relationship between perceived risk and performance outcome, indicating that risk awareness and risk perception play an important role in risk management:

| High Performance High Risk |

Low Performance High Risk |

| High Performance Low Risk |

Low Performance Low Risk |

Conclusion

The article establishes a generic framework for supply chain risk management. It is prosaic and conceptual in its approach, and it leaves much unanswered while raising some fundamental issues for future consideration. These are the conclusion I have drawn from this article:

- Supply Chain Risk Management cannot be defined once and for all, it is unique to every supply chain and must be assessed for each supply chain individually.

- Supply Chain Risk Management is an intricately interwoven concept. It involves not only the whole supply chain, but the whole organization and the wider relationships with other organizations and supply chains.

- Supply Chain Risk Management involves expenditures that do not seem to relate to the overall performance of a business, and thus, there is a need to develop metrics that can link risk and performance.

While published as two separate papers, both An emergent framework for supply chain risk management and performance measurement and Supply chain risk management and performance: A guiding framework for future development should be read together, since they both complement each other.

Reference

Ritchie, B., & Brindley, C. (2007). Supply chain risk management and performance: A guiding framework for future development International Journal of Operations & Production Management, 27 (3), 303-322 DOI: 10.1108/01443570710725563

Links

- linkedin.com: Professor Clare Brindley

- linkedin.com: Professor Bob Ritchie