A supply chain as a virtual enterprise network. That is the underlying reasoning in the 2009 paper How to improve supply chain flexibility using strategic supply chain networks by Herwig Winkler. Virtual Enterprise Networks do not play a major role in this paper, but what fascinates me are (1) the parameters defining supply chain flexibility: Transparency, Simplicity, Responsiveness/Agility and Security/Reliability, and (2) flexibility potentials: Structural, Technological and Human flexibility potentials.

A supply chain as a virtual enterprise network. That is the underlying reasoning in the 2009 paper How to improve supply chain flexibility using strategic supply chain networks by Herwig Winkler. Virtual Enterprise Networks do not play a major role in this paper, but what fascinates me are (1) the parameters defining supply chain flexibility: Transparency, Simplicity, Responsiveness/Agility and Security/Reliability, and (2) flexibility potentials: Structural, Technological and Human flexibility potentials.

Basics of flexibility

Flexibility is an important addition to the more traditional topics of supply chain management, such as quality, cost, time and service, and Winkler defines flexibility as

the ability of a system to perform proactive and reactive adaptations of its configuration in order to cope with internal and external uncertainties.

Note the terms proactive and reactive here. Is it possible to say that proactive is flexibility and reactive is agility?

Strategic Supply Chain Networks

Supply Chain Flexibility is here seen as prerequisite for gaining competitive advantage and improving business success. To improve the flexibility of a supply chain Winkler suggests building up and using strategic supply chain networks.

A strategic supply chain network is characterised by a selected circle of supply chain members, a collective identity, an internal role differentiation and power division, the delegation of responsibility, its’ limited permanence, the possibility to transpose members, and a rational procedure for the realization of common targets executed by all of the participating companies. The strategic supply chain network is a virtual organization because every embedded member remains independent while participating in the network.

It is interesting to see how Virtual Organizations or Virtual Enterprise Networks slowly but surely are making their way into regular Supply Chain Management theory. It’s not often that I come across this term in journals not specifically dedicated to this subject.

Winkler notes that

To design and manage a strategic supply chain network, the SCM has the task of first establishing an effective structure within the supply chain, and secondly, to guarantee on an efficient performance. The tasks of an SCM can be assigned to the life cycle. It is here that we differentiate between the stage of design, performance, development and termination.

The supply chain life cycle is not often touched upon in SCM literature, and it is only rarely that I encounter papers or books dealing with with life cycle concept. This is another reason for me to wholeheartedly enjoy the holistic approach that Winkler uses.

Literature Review

The literature review centers around some highly recommendable papers,

- Barad, M., & Sapir, D. E. (2003). Flexibility in logistic systems—modeling and performance evaluation International Journal of Production Economics, 85(2), 155-170

- Das, S. K., & Abdel-Malek, L. (2003). Modeling the flexibility of order quantities and lead-times in supply chains International Journal of Production Economics, 85(2), 171-181.

- Duclos, L. K., Vokurka, R. J., & Lummus, R. R. (2003). A conceptual model of supply chain flexibility. Industrial Management and Data Systems, 103(5/6), 446-456.

- Garavelli, A. C. (2003). Flexibility configurations for the supply chain management International Journal of Production Economics, 85(2), 141-153.

- Lummus, R. R., Duclos, L. K., & Vokurka, R. J. (2003). Supply Chain Flexibility: Building a New Model. Global Journal of Flexible Systems Management, 4(4), 1-13.

- Sanchez, A. M., & Perez, M. P. (2005). Supply chain flexibility and firm performance: A conceptual model and empirical study in the automotive industry. International Journal of Operations & Production Management, 25(7), 681-700.

- Vickery, S., Cantalone, R., & Dröge, C. (1999). Supply Chain Flexibility: An Empirical Study. Journal of Supply Chain Management, 35(1), 16-24.

highlighting the various concepts and interlinking the various definitions of flexibility and the consequent implications for supply chain flexibility.

The framework

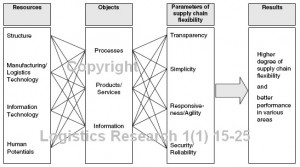

Winkler’s framework appears complex, but it is stunningly simple:

He links supply chain resources with supply chain objects, i.e. subjects of modification to achieve flexibility, which is measured using a set of parameters, which reflect the results of the flexibility improvement (or not).

Supply Chain Flexibility Parameters

In order to judge the supply chain flexibility of the strategic supply chain network, Winkler proposes at set of flexibility parameters:

Transparency

- T = (Σ j=1:n Known SC elementsj / Σ i=1:m SC elementsi) X 100

Simplicity

- S = (1 / Σ i=1:m SC elementsi) X 100

Responsiveness/Agility

- RA = (Σ j=1:n Standardized SC elementj / Σ i=1:m SC elementi) X 100

Security/Reliability

- SR = f (quality of SC elements)

Winkler admits that more parameters can be set up, but he has limited himself to these four.

Supply Chain Flexibility Potentials

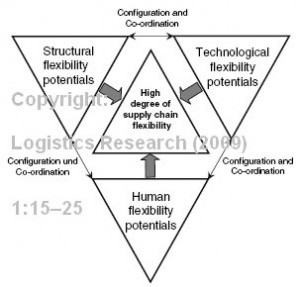

As already mentioned above, within strategic supply chain networks specific flexibility potentials can be developed to realize a high degree of supply chain flexibility:

I am very fond of this figure. Simple, yet all-encompassing. I am always impressed with scholars who manage to express their ideas in figures that are easy to comprehend. It shows an ability not only to truly understand their own subject matter but also an ability to convey their message in a clear manner to an audience unfamiliar with the subject matter.

Critique

If there is one thing I would want to disagree with here, it is the definition of responsiveness/agility, or rather the lacking definition of agility as I see it. In my world agility and flexibility are inherently different. Flexibility is scheduled or planned adaption to unforeseen yet expected external circumstances. Agility is unplanned and unscheduled adaption to unforeseen and unexpected external circumstances. With Winkler, agility seems to be a function of how standardized the supply chain is. That said, it does make sense that more operationally standardized a supply chain is, the more responsive it can be.

What is also lacking is a better definition of what constitutes quality of supply chain elements besides referring to the obvious need for high quality in order to gain sufficient flexibility.

I would also have liked to see a clearer expansion of the virtual enterprise concept, albeit it is present in much of the paper.

A new Journal

The article is printed in the first issue of the first volume of Logistics Research, a new journal with an interesting mixture of listed topics: Engineering, Engineering Economics, Organization, Logistics, Marketing, Production/Logistics, Industrial and Production Engineering, Philosophy of Language, Operations Research/Decision Theory and Commercial Law. So far, though, judging only by the first two issues, the topics have centered around logistics and supply chain management, and I have already found a number of interesting papers that I will come back to on this blog.

Reference

Winkler, H. (2008). How to improve supply chain flexibility using strategic supply chain networks Logistics Research, 1 (1), 15-25 DOI: 10.1007/s12159-008-0001-6

Author link

- uni-klu.ac.at: Herwig Winkler

- linkedin.com: Herwig Winkler

Related

- husdal.com: Book Review: Cooperative Strategy

- husdal.com: Managing Risk in Virtual Enterprise Networks

- husdal.com: A conceptual model for supply chain flexibility