A severe supply chain disruption has hit my own blog: More than a month without a post. It’s not that there is so little to write about, it’s just that there is so little time to do it, which is why I’ve decided to reurn to a once weekly posing schedule. Nonetheless, what better occasion could there be to resume my posting than the discovery of an article proclaiming to provide a review of the state of the art in supply chain risk management? The literature review and conceptual framework developed by Hans-Christian Pfohl, Holger Köhler and David Thomas clearly identifies the main principles of SCRM and develops a framework and definitions for disturbance, disruption, security, resilience and risk. Supply chain risk management, so they say, is a process with evolutionary steps, involving no less than 17 underlying principles. Phew…

A severe supply chain disruption has hit my own blog: More than a month without a post. It’s not that there is so little to write about, it’s just that there is so little time to do it, which is why I’ve decided to reurn to a once weekly posing schedule. Nonetheless, what better occasion could there be to resume my posting than the discovery of an article proclaiming to provide a review of the state of the art in supply chain risk management? The literature review and conceptual framework developed by Hans-Christian Pfohl, Holger Köhler and David Thomas clearly identifies the main principles of SCRM and develops a framework and definitions for disturbance, disruption, security, resilience and risk. Supply chain risk management, so they say, is a process with evolutionary steps, involving no less than 17 underlying principles. Phew…

Terminology definitions

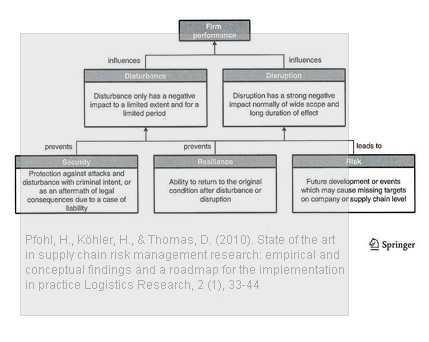

The article attempts to define many of the common terms that any researcher in supply chain risk juggles daily, albeit “supply chain risk” itself is not defined; they only refer to a number of definitions in the literature, acknowledging that supply chain risks have to be considered from a wide and complex range of perspectives. Nonetheless, the develop a framework of how certain elements of supply chain risk contribute positively or negatively to the overall firm performance:

Here the authors identify security, resilience, risk, disturbance and disruption is key factors that need to be considered in supply chain risk management.

Implementing supply chain risk management

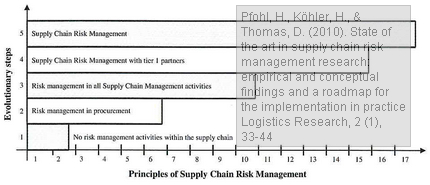

What I like about this article is what they call the roadmap towards supply chain risk management, where they define 17 principles, which, if taken in the right order, signal an evolution of a firm’s risk management from having none to full and integrated supply chain risk management:

The principles are as follows:

- The focus of risk management is across company boundaries.

- The company knows its supply chain in and out.

- SCM and SCRM are seen as integrated and not independent from each other.

- Internal RM and SCRM are coordinated and integrated.

- SCRM is part of the overall corporate strategy.

- Top management supports and is responsible for SCRM.

- (All) actors in the supply chain have a mutual understanding of potential risks.

- Risk information is available to (all) actors in the supply chain.

- (All) actors in the supply chain have a close, cooperative and fair relationship.

- (All) actors in the supply chain trust each other mutually.

- Information asymmetries do not exist.

- (All) actors take part in mutual goals and planning processes in the supply chain.

- Risk information is exchanged between (all) actors in the supply chain.

- Direct supply chain partners cooperate in their SCRM.

- (All) actors in the supply chain share risks and the rewards achieved.

- All actors in the supply chain are involved in SCRM, both internally and externally.

- All actors in the supply chain aim at the same goals in SCRM.

These 17 principles can be applied to a 5-stage evolution like this:

- No significant risk management activities in the supply chain

- Risk management in procurement

- Risk management in all supply chain activities, mainly restricted to tier 1 suppliers

- Cooperative risk management with tier 1 suppliers, tier 2 and customers

- Fully integrated supply chain risk management at all supply chain levels and connections

Note here that it it is possible for a company to be at different stages with different supply chain partners or to use different principles with different partners.

Conclusion

I may not subscribe fully to all principles or the five steps, but it does provide a framework or guideline for how to approach and assess supply chain risk management. Furthermore, the article provides insights and discussion of much of the seminal literature on supply chain risk, boosting some 68 references, many of which in German, though. I’m not sure I would agree with “state of the art”, but certainly a highly valuable contribution.

Reference

Pfohl, H., Köhler, H., & Thomas, D. (2010). State of the art in supply chain risk management research: empirical and conceptual findings and a roadmap for the implementation in practice Logistics Research, 2 (1), 33-44 DOI: 10.1007/s12159-010-0023-8

Author links

- tu-darmstadt.de: Hans-Christian Pfohl

- tu-darmstadt.de: Holger Köhler

- tu-darmstadt.de: David Thomas

Related

- husdal.com: SCRM – a complete review?