Operations Rules by David Simchi-Levi comes with an ambiguous title. You can read this two ways: 1) Operations Management (over)rules Supply Chain Management or 2) The Rules of (Business) Operations Management. Either way, this is an excellent book with a broad scope. Most importantly perhaps, it contains an extensive chapter on managing supply chain risk, something that is very rare in the average book on supply chain management. That should not come as a surprise, however, because this is not an average book. It is one of the most applicable and practically oriented books on supply chain operations that has come across my desk in recent times.

Operations Rules by David Simchi-Levi comes with an ambiguous title. You can read this two ways: 1) Operations Management (over)rules Supply Chain Management or 2) The Rules of (Business) Operations Management. Either way, this is an excellent book with a broad scope. Most importantly perhaps, it contains an extensive chapter on managing supply chain risk, something that is very rare in the average book on supply chain management. That should not come as a surprise, however, because this is not an average book. It is one of the most applicable and practically oriented books on supply chain operations that has come across my desk in recent times.

Not a dull moment

Amazingly, I did not have a dull moment where I felt like skipping a page or two when reading this book. The starting point is that every company has its unique customer value proposition, be it Zara’s high end fashion at a reasonably price or Wal-Mart’s everyday low pricing, but

No firm can compete successfully on all dimensions of customer value, such as innovation, choice, price and experience. Management needs to pick its goals, since operations and supply chain strategies, the market channel, or even the skill sets required to be successful depend on the specific value proposition.

That is perhaps where many firms fail, as no firm can be extremely efficient and compete on price and at the same time be extremely responsive and compete on a wide range of choices. It is simply not possible, as companies tend to be either highly efficient or highly responsive, but not both. Simchi-Levi, however, shows how to match value propositions and strategies, and how to achieve the best possible tradeoff between efficiency and responsiveness.

33 rules of operations

The book takes on a very unique approach that I haven’t seen before: The book is built around 33 rules that cover all possible aspects of supply chain operations and management, and that are placed throughout the eleven chapters of the book, hence the title. Many of these rules stem from anecdotes and examples of companies that failed or succeeded in their efforts. These stories are at the heart of this book, a book that is about the principles, frameworks and processes that enable the aligning of a company’s specific customer value proposition with its operations strategy.

In the first part, the book first looks at how customer value proposition translates into operations strategy, and then, how a firm can match products and markets with the appropriate strategies. Here, procurement and supply contracts, if used well, can turn into competitive weapons, and risk mitigation is highlighted as an important element of operations strategy.

In the second part, flexibility is presented as the key enabler for successful supply chain operations, that is flexibility in system design, flexibility in process design, and flexibility in product design. System design flexibility refers to manufacturing, distribution or capacity redundancy. Process design flexibility would include a flexible workforce, worker cross-training, lean manufacturing and different procurement strategies. Product design flexibility includes modular product architecture, standard components and interfaces, postponement and component substitution.

The final and third part of the book addresses two important emerging trends: oil price volatility and corporate social responsibility. Here, Simchi-Levi shows that the latter is much more than simply charity, philanthropy or compliance with environmental regulations, and making the supply chain greener. In fact, corporate social responsibility can be a considerable revenue opportunity that many companies tend to overlook.

Risk Sources

It is perhaps not fair to judge the importance of a chapter by its length, but fact is that the chapter on risk mitigation is 30 pages, while most other chapters are 15-17 pages, and it is not because this chapter is full of figures. It is, but so are the other chapters, too. To me this is a clear indication that Simchi-Levi sees risk mitigation as an integral part of operations and supply chain management.

Indeed, current industry trends correlate directly to the rising risk levels in the supply chin. As offshoring and globalization of manufacturing operations continue to grow, supply chains are geographically more diverse and therefore exposed to various types of natural and man-made disasters.

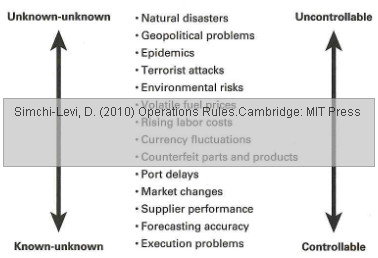

These thoughts are very similar to what appears in Martin Christopher’s book on supply chain management, but where Christopher only scratches the surface, Simchi-Levi goes further. Interestingly, Simchi-Levi divides risk sources along two dimensions: Known-Unknown and Controllable-Uncontrollable.

Popularized by George Rumsfeld, the Unknown-Unkowns are risks that are difficult to predict, while the Known-Unknowns are more likely be forecasted based on statistical data, e.g. supplier lead time or time between equipment failures.

Risk Assessment

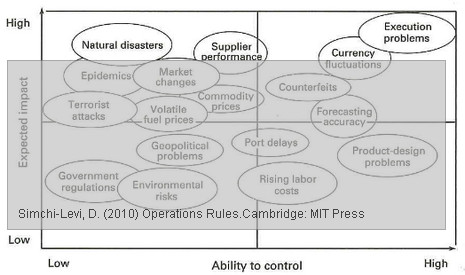

While the traditional way of assessing risk is by evaluating predictability and expected impact, Simchi-Levi discards the former in favor of controllability, since in the end the ability to control is more important than the ability to predict. Consequently, he suggests that management needs to develop risk mitigation strategies that depend on the expected impact on business performance.

This is very similar to what Stephan Gundel suggests in his typology of crises, albeit Gundel still uses predictability, but uses controllability as his second dimension, albeit prefers the term influenceable to controllable.

Risk Mitigation

According to Simchi-Levi, there are three strategies that a firm can employ to manage supply chain risk, particularly the Unknown-Unknowns:

- creating capacity redundancy,

- increasing velocity in sensing and responding, and

- adding flexibility to the supply chain.

Together, these methods create a resilient supply chain, as each method focuses on a different supply chain dimension. Capacity redundancy needs to be built in at the design stage, speed in sensing and responding requires accurate and timely information, and a flexible supply chain community requires partners that embrace flexibility, work towards the same objectives, and are willing to share the costs and benefits.

Using Mexico based CEMEX as an example, Simchi-Levi illustrates the benefit of rule #1 integrate risks into operational and business decisions, showing how CEMEX regards risk management as core competence, as described by Lessard and Lucea (2009). Rule #2 supply chain cost is always flat around the optimal strategy points to capacity redundancy and the issue of tradeoff when looking at where to locate manufacturing plants, as seen in Snyder and Daskin (2005). Finally, rule #3 invest now or pay the price later, is the classic example of how Nokia and Ericsson and how two different supply chain strategies lead to two very different impacts resulting from the same supply chain disruption.

Simchi-Levi also touches briefly on managing global supply chain risks, suggesting speculation, hedging and flexible manufacturing and sourcing as key ingredients here, and describes them in a clear and concise manner. While speculation takes a certain scenario for granted, which may or may not come true, hedging speculates both ways and may incur a loss in one place, while being a success in a different place. Flexible manufacturing and sourcing allows for moving products and processes to the location that is most cost-efficient, regardless of external circumstances, e.g. currency fluctuations.

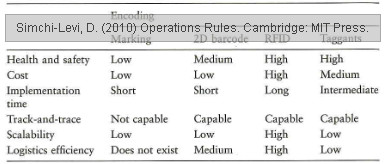

The last part of the chapter on risk mitigation strategies deals with an important issue: counterfeit products. Globalization, for all its good, has also increased the chance that counterfeit products may enter the supply chain somewhere along the complicated and long way from the supplier to the end customer, Simchi-Levi discusses what can be done. He suggests four main strategies for supply chain security management: 1) Supplier selection (choosing only authorized dealers), 2) Marking (e.g. only visible in UV-light), 3) Barcodes, 4) RFID and 5) Taggants, which must be evaluated based on 1) their ability to protect public health and safety, 2) their cost and implementation time, 3) their track and trace capability, 4) their scalability, and 5) whether they can provide logistics efficiencies or not.

The advantages and disadvantages of the various technologies suggests that the appropriate approach to counterfeit products depends on product, industry and level of sophistication expected from an adversary.

Conclusion

Simchi-Levi is a true well of knowledge as far as supply chain management is concerned, and it shows. Not only are his rules based on a plethora of examples and anecdotes of firms that succeed or failed in their risk management, the examples themselves have a broad scope, in geography, in impact and in industry. Someone (i.e. Simchi-Levi) has done their homework with this one. There is hardly a point made that is not followed by an example, e.g. CEMEX or Nokia/Ericsson. I find that very impressive, and it also shows the universal applicability of this book, and the risk chapter has made me rethink the structure of my 2011 lecture on supply chain risk, and perhaps I will use Simchi-Levi this year, and not Christopher Tang’s nine robust strategies for mitigating supply chain disruptions? This is a book I can wholeheartedly recommend, and this is not the last time it will be featured on this blog, because I have yet to present the chapters on flexibility and on corporate social responsibility, which along with risk mitigation are my favorite parts of this book.

Reference

Simchi-Levi, D. (2010) Operations Rules: Delivering Customer Value Through Flexible Operations. Cambridge: MIT Press.

Author link

- mit.edu: David Simchi-Levi

Buy this book

- amazon.com: Operations Rules

Official book website

- operationsrules.com: Operations Rules

- operationsrules.com: Download sample chapter

Related link

- oprules.com: Operations Rules News