We are living in turbulent times. So are our supply chains. Nonetheless, the standard tenets of supply chain management prescribe that supply chains are most efficient when fully controlled from end to end, without any volatility or uncertainty. The basic idea is that variability is detrimental to performance as it causes cost in the form of stock-outs, poor capacity utilisation, and costly buffers. Really? Martin Christopher and Matthias Holweg disagree, and that is why they wrote “Supply Chain 2.0”: managing supply chains in the era of turbulence. This paper questions the established approach and argues that in the light of increasing turbulence a different approach to supply chain management is needed. What is needed is an approach that builds structural flexibility into the supply chain decision making. Only thus can we create the level of adaptability that is needed to remain competitive in the face of turbulence.

We are living in turbulent times. So are our supply chains. Nonetheless, the standard tenets of supply chain management prescribe that supply chains are most efficient when fully controlled from end to end, without any volatility or uncertainty. The basic idea is that variability is detrimental to performance as it causes cost in the form of stock-outs, poor capacity utilisation, and costly buffers. Really? Martin Christopher and Matthias Holweg disagree, and that is why they wrote “Supply Chain 2.0”: managing supply chains in the era of turbulence. This paper questions the established approach and argues that in the light of increasing turbulence a different approach to supply chain management is needed. What is needed is an approach that builds structural flexibility into the supply chain decision making. Only thus can we create the level of adaptability that is needed to remain competitive in the face of turbulence.

Supply Chain Turbulence

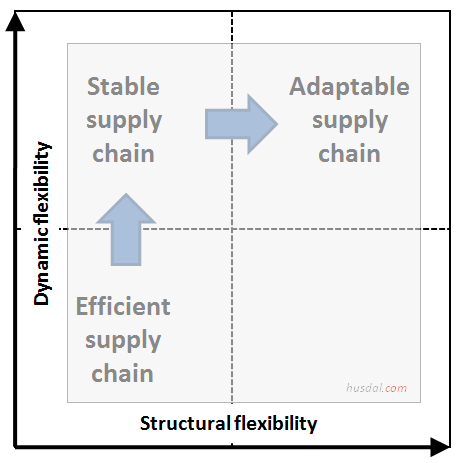

“Turbulence” seems to be a new and coming buzzword in supply chain (risk) management, and many of my readers may remember some of my earlier posts on this topic. It first appeared in my review of Peter Trkman’s article on supply chain risk in turbulent environments, and later, in an article on supply chain confidence by Martin Christopher and Hau Lee. Turbulence is volatility is uncertainty and something that supply chains have always had to deal with. The difference is that with global supply chains, any volatility, even if far away, can cascade through the supply chain in no time and translate into a severe disturbance and loss of profit, if not acted upon. Moreover, volatility will make your shareholders uneasy, as Hendricks and Singhal wrote in their 2003 article.

Similar, but not really?

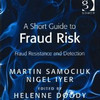

Reading through the article and looking at the figure above, the concept of structural versus dynamic flexibility bears a striking resemblance to the lean-agile-leagile discussion some years ago. It is also similar to flexibility versus agility, where agility is unplanned and unscheduled adaptation to unforeseen and unexpected external circumstances, and where flexibility is scheduled or planned adaptation to unforeseen yet expected external circumstances. This would make agility a case for dynamic flexibility, whereas flexibility comes closer to structural flexibility, or maybe structural flexibility is the marriage of agility and flexibility?

Supply Chain 1.0 versus 2.0

Traditionally, supply chains have responded to variability and uncertainty by adding measures of control and stability. This has promoted a plethora of operational practices such as Lean, Six Sigma, push-based production, vendor-managed inventory and many more successful an less successful attempts. Although seemingly effective, these are very specific strategies geared towards certain industries and/or certain products, and although many companies have managed to build dynamic flexibility into their supply chains by being able to quickly reacting to changes, these are more like contingency plans than actual structural changes to the supply chain.

Structural flexibility defined

What exactly is structural flexibility? Well, according to Christopher and Holweg it refers to the ability of the supply chain to adapt to fundamental changes in the business environment. This, so they say, is done by first and foremost designing the supply chain for flexibility, not for efficiency, which is the case with most supply chains today, where flexibility is a sort of added option. In a structurally flexible supply chain, flexibility takes center stage, and efficiency becomes the second violin. I find that an interesting thought.

Structural flexibility implies the use of the following strategies:

- Dual sourcing

- Asset sharing with other companies, including competitors

- Separating base demand from surge demand

- Postponement of final product assembly

- Flexible labor arrangements

- Rapid manufacturing of small batches

- Outsourcing and contract manufacturing

In the efficient supply chain, the focus is on control and the aim is to reduce too much variability. In the adaptable supply chain the focus is on volatility and the aim is to develop a superior ability to adapt. The former sees turbulence as bad for business. The latter sees it as inevitable and thus creates adaptable structures to accommodate it. While the efficient supply chain tries to eradicate turbulence, the adaptable supply chain embraces it and works with it.

Conclusion

I am not sure that “Supply Chain 2.0” is what most appropriately describes structural flexibility, besides being a “catchy” title, and I do like papers with catchy titles, but I think Christopher and Holweg are on the right track here. We should not fight volatility, we should perhaps not welcome it either, but we should not view it as an enemy.

Reference

Christopher, M., & Holweg, M. (2011). “Supply Chain 2.0”: managing supply chains in the era of turbulence International Journal of Physical Distribution & Logistics Management, 41 (1), 63-82 DOI: 10.1108/09600031111101439

Author links

- martin-christopher.info: Martin Christopher

- cam.ac.uk: Matthias Holweg

Related

- husdal.com: Supply chain resilience and confidence

- husdal.com: Supply chain risk in turbulent environments