Why haven’t I seen this paper before? And why is it not cited more often? It should. It is called The role of elasticity in supply chain performance and was written by Bradley Hull in 2005, and it develops a model that describes the performance of supply chains based on their elasticities of supply and demand. The model can be used to predict a supply chain’s ability to respond to supply interruptions, cost increases, and demand shifts, while also quantifying the degree to which it is prone to the bullwhip effect. The paper identifies four types of supply chains and examines their distinct operating characters, in particular the impact of rival firms and the impact of a decoupling point on supply chain performance. What more can you ask for? It’s all here.

Why haven’t I seen this paper before? And why is it not cited more often? It should. It is called The role of elasticity in supply chain performance and was written by Bradley Hull in 2005, and it develops a model that describes the performance of supply chains based on their elasticities of supply and demand. The model can be used to predict a supply chain’s ability to respond to supply interruptions, cost increases, and demand shifts, while also quantifying the degree to which it is prone to the bullwhip effect. The paper identifies four types of supply chains and examines their distinct operating characters, in particular the impact of rival firms and the impact of a decoupling point on supply chain performance. What more can you ask for? It’s all here.

Supply and demand elasticity explained.

I am not an economist by education, and not much of an an economist by training. However, in my daily line of work I often have to consider the macro- and microeconomics of supply and demand, and this paper makes it almost effortless to understand these concepts. Admittedly, not everything in this paper is equally easy to read and comprehend, but it’s rare to see a paper that brings it all together so comprehensively.

Adapt or Die

The author’s starting point is that in order to achieve top performance, a supply chain must adapt to or solve two issues, one downstream and one upstream.

First, the supply chain must ‘‘fit’’ the market characteristics of the products it distributes.

Obviously.

Second, it must overcome the well-documented bullwhip effect.

Is there really a bullwhip effect in all supply chains? Ever since this concept was made popular by Lee et al. (1997), it has been accepted as the truth about supply chains, although not all bullwhips are bullwhips, as The Operations Room reports.

See and learn

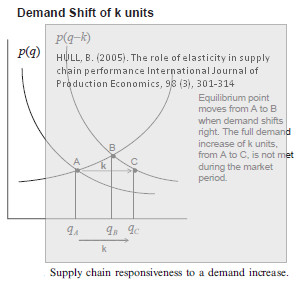

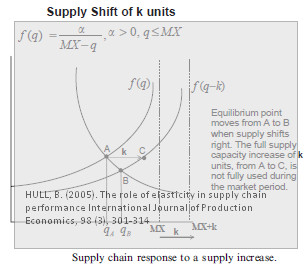

In the midst of some elaborate equations, the paper displays the effects of shifts in supply and demand on the supply chain. I have to admit that the interpretation supply and demand curves are not my strong side, but these look almost self-explanatory:

Supply Chain Performance metrics

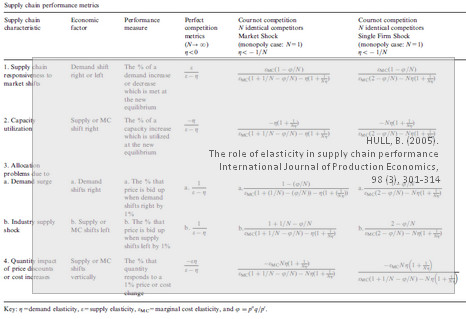

The paper argues that it is important to quantitatively gauge the performance of a supply chain, and that there are four question that are central to developing performance metrics:

(1) If demand for a product suddenly increases, what percent of that increase can its supply chain deliver during the market period?

(2) If capacity is added to a supply chain, what percent of this increase will the market absorb during the market period?

(3) If allocation problems are caused by either a supply interruption or asudden demand increase, how severe will they be?

(4) If supply costs increase or a supplier offers a discount, what will be the likely impact on throughput?

These questions, and the metrics for answering them, are presented in a neat table:

Supply chain classification

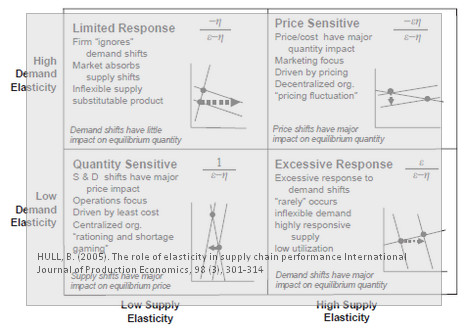

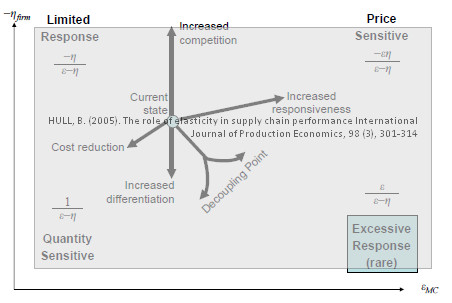

Based on high and low supply and demand elasticity, the paper puts forward a classification scheme showing four types of supply chains:

- Low demand + Low supply elasticity = Quantity sensitive supply chain

- High demand + Low supply elasticity = Limited response supply chain

- High supply + low demand elasticity = Excessive response supply chain

- High supply + High demand elasticity = Price sensitive supply chain

Again, the figure is self-explanatory:

Taking a closer look, the figure above is not so unlike the agile-lean-leagile concept I posted about earlier.

Supply chain dynamics

The final excellent figure from the paper is a figure that shows how a supply chain can develop, from a current state and towards the four types described above.

Again I am impressed with the author’s ability to capture difficult concepts in a simple image.

Conclusion

This paper was a pleasant surprise, and it didn’t look like it would be from the outside, but even I, the self-proclaimed non-quantitative researcher, thoroughly enjoyed learning more about the so-called Cournot competition and everything else that can be linked to supply and demand thanks to this literally illustrative article. So why is not cited more often? According to Scopus, only nine times since its inception. Perhaps, because the average supply chain researcher is deterred by the word “elasticity”? I was too…before I read it. Not anymore.

Reference

HULL, B. (2005). The role of elasticity in supply chain performance International Journal of Production Economics, 98 (3), 301-314 DOI: 10.1016/j.ijpe.2004.09.013

Author links

- jcu.edu: Bradley Hull

Download

- rayaamoozesh.com: The role of elasticity in supply chain performance

Related posts

- husdal.com: Lean – Agile – Leagile

demand. The model can be used to predict a supply chain’s ability to respond to supply interruptions, cost increases,

and demand shifts, while also quantifying the degree to which it is prone to the bullwhip effect