Supply chain flexibility is a decisive factor in avoiding supply chain disruptions. One major contributor to supply chain flexibility is the flexibility of the logistics provider, and Mohamed Naim, Gilbert Aryee and Andrew Potter have just published a paper about this. In Determining a logistics provider’s flexibility capability they aims to develop the construct of transport flexibility within the context of supply chain strategy. We assess the role of flexibility in satisfying competitive opportunities while accommodating supply chain uncertainties. In this way, we may then determine the role of different transport flexibility types in delivering strategic outcomes.

Supply chain flexibility is a decisive factor in avoiding supply chain disruptions. One major contributor to supply chain flexibility is the flexibility of the logistics provider, and Mohamed Naim, Gilbert Aryee and Andrew Potter have just published a paper about this. In Determining a logistics provider’s flexibility capability they aims to develop the construct of transport flexibility within the context of supply chain strategy. We assess the role of flexibility in satisfying competitive opportunities while accommodating supply chain uncertainties. In this way, we may then determine the role of different transport flexibility types in delivering strategic outcomes.

Supply Chain Flexibility

Today’s article builds on the previous work by Naim, Potter and associates, who employ a triad (supplier – carrier customer) perspective on the supply chain, contrary to the more popular dyad (supplier – customer) perspective. Personally, I am compelled to agree with the triad being the more correct view, particularly when addressing flexibility:

While much of the research on flexibility has focused on the product delivery process, within and between businesses in the supply chain, little attention has been paid to the role of transport, a key operational function enabling the flow of materials and resources between suppliers and customers. Also there is limited research on transport flexibility as an enabler for supply chain flexibility. And yet there is an underlying premise in the supply chain that logistics providers will respond to changes in demand and be willing to accommodate uncertainties.

The latter is a notion that I have come across myself, in my own research on how Norwegian freight carriers handle transportation disruptions:

Transportation disruptions do not seem to be a major concern for transportation-dependent businesses, because both mitigative and contingent measures are sufficiently handled by the freight carrier. The freight carriers carry the risk of transportation disruptions, not the businesses or manufacturers.

Unfortunately, while transport flexibility is what creates much of supply chain flexibility, the role that transportation providers play in supply chains is often underestimated or not estimated at all.

Case study

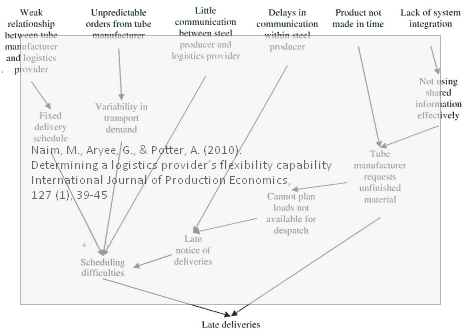

Using their previous model of internal and external flexibility, the case study in the paper is a steel supply chain consisting of a steel producer, a steel tube manufacturer and a logistics provider. The case shows how the interplay of these three, or perhaps rather the lack of interplay, causes supply disruptions, i.e. late deliveries:

Conclusion

It is only recently that I came across the work of Naim and his fellow researchers, and this article truly highlights the importance that transportation and logistics have in improving supply chain performance and supply chain flexibility. Unlike their previouswork, this article does not break new ground so to speak, but I found many references on manufacturing and transportation flexibility I hadn’t heard of before, and I look forward to reviewing more of their research in future blog posts, since we seem to have similar research interests.

Reference

Naim, M., Aryee, G., & Potter, A. (2010). Determining a logistics provider’s flexibility capability International Journal of Production Economics, 127 (1), 39-45 DOI: 10.1016/j.ijpe.2010.04.011

Author links

- cardiff.ac.uk: Mohamed Naim

- linkedin.com: Gilbert Aryee

- cardiff.ac.uk: Andrew Potter

Related posts

- husdal.com: Flexing your SCM muscles

- husdal.com: How Norwegian freight carriers handle disruptions