Should short-term loss-minimization and short-term profit maximization really be the driving force behind supply chain risk management? In their 2009 article Weak links in the supply chain: measuring fragility and sustainability, Peter Stonebraker, Joel Goldhar and George Nassos point at a emerging area of supply chain research: fragility and sustainability, and they develop a framework for understanding and measuring it. Conceptually intriguing, the paper weaves together corporate responsibility, supply chain disruptions and long-term supply chain sustainability in a holistic picture going far beyond much of the loss-oriented supply chain risk literature of recent years.

Should short-term loss-minimization and short-term profit maximization really be the driving force behind supply chain risk management? In their 2009 article Weak links in the supply chain: measuring fragility and sustainability, Peter Stonebraker, Joel Goldhar and George Nassos point at a emerging area of supply chain research: fragility and sustainability, and they develop a framework for understanding and measuring it. Conceptually intriguing, the paper weaves together corporate responsibility, supply chain disruptions and long-term supply chain sustainability in a holistic picture going far beyond much of the loss-oriented supply chain risk literature of recent years.

The concepts of fragility and sustainability

It took me a while to get my head around the concept of fragility and sustainability, since unfortunately, both terms are poorly defined in the article, and when I say poorly defined I mean that there is no obvious or highlighted statement that says “fragility is…” or “sustainability is…”. Fragility and sustainability are defined in terms of each other; the section on fragility talks a lot about sustainability, and vice versa, and there are many examples…but I finally came to an understanding:

A supply chain is fragile if it is not sustainable or prone to disruptions in a long-term perspective.

A sustainable supply chain is seen as robust, while a unsustainable supply chain is seen as fragile.

The time dimension

What helps in the understanding of supply chain fragility is to add a dimension of time to the concept of supply chain, where raw materials flow from one end to the other end, the final customer, and back, in terms of recycling. In a normal, profit-seeking business environment this implies that as time goes by, there will be an increased demand for resources, while at the same time, there will be a decreased supply of resources. While each supplier along the chain sees an business opportunity, each consumer along the chain has to face the uncertainty of insufficient supply, due to both internal and external factors, and over time this network of intertwined supply chain actors can become fragile, particularly as resources are depleted, or simply because of the network’s own system dynamics.

How to measure fragility

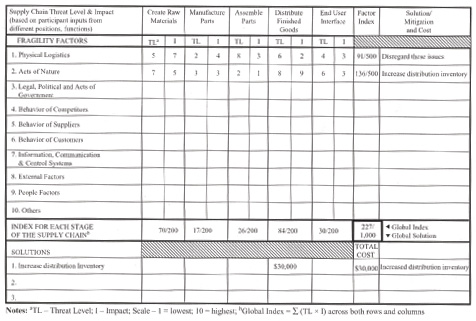

Applying the supply chain stages of the SCOR framework, each stage is evaluated for the Threat Level and Impact of each Fragility Factor, assigned a score between 0 and 10, and then summed up in a Global Fragility Index, expressed as

∑ (TLS * IS)/(S * F)

where TLS = Threat Level at stage s, IS = Impact at stage s, S is the number of stages in the SCOR model (i.e. = 5, see below), and F is the number of Fragility Factors (e.g. = 10, see below).

Copyright note: The figure above is taken from the article.

Each stage will have a stage index, and each factor will have factor index.

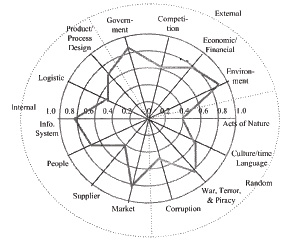

Copyright note: The figure above is taken from the article.

The final results are then plotted on a fragility index matrix.

SCOR stages

- Acquire Raw Materials

- Manufacture Parts

- Assemble Parts

- Distribute Finished Goods

- End User

Fragility Factors

- Internal

- Physical logistics

- Behavior of suppliers

- Behavior of customers

- Information, communication and control systems

- Product and process design

- People

- External

- Legal, political, acts of government

- Behavior of competitors

- Economics and finance

- Environmental impact

- Unanticipated/ random events

- Acts of nature

- Other external factors

- Other factors

Note the two last factors, both are named “other” and classified as 1) war, terrorism and piracy, distance and time, language and culture, and 2) corruption, subversion, lack of cooperation, and failure of communication. Personally I find this too undiscerning and lacking clarity, more like “anything else not covered above”. In my mind, war, terrorrism, and piracy should be grouped with corruption and subversion as one, which we could call “Acts of man”, while distance and time, language and culture, lack of cooperation and failure of cooperation could be grouped as “human-related” factors, just as much internal (people) as it is external. Interestingly, maybe the author realized this inconsistency, because in their on example when presenting the fragility index matrix, when going from the index calculation sheet to drawing the matrix, 10 factors have suddenly become 14 …separated so “for ease of reference”…duh. Nonetheless, the concept is methodically sound, and the number of factors may in fact be of lesser interest, since they will have to aligned with the commonalities in the supply chain stages that are to be investigated. However, the paper would have fared better with a little bit more consistency.

Does it matter?

It does, because the cash-to-trash cycle is a reminder that all things must end, and in the end, sustainable is more profitable. As the authors put in their final paragraph,

Careful identification, modeling and representation of the fragility factors and the fragility index matrix would demonstrate effective management and provide a basis for continuous improvement…

What it comes down to is the visible hand of management (the hand that leads to improvement) against the invisible hand of the economy (the hand that ultimately leads to disaster).

Reference

Stonebraker, P., Goldhar, J., & Nassos, G. (2009). Weak links in the supply chain: measuring fragility and sustainability Journal of Manufacturing Technology Management, 20 (2), 161-177 DOI: 10.1108/17410380910929600

Author links

- linkedin.com: Peter Stonebraker

- iit.edu: George Nassos

- iit.edu: Joel Goldhar

Related

- husdal.com: Are you the weakest link in the supply chain?