Are you the weakest link in your own supply chain? That’s the question asked in an article in the Harvard Business Review some time ago. The article is geared towards company CEOs, advising them not to get too detached from supply management, but rather to actively engage in their company’s supply chain management, particularly in businesses like manufacturing, retail and distribution. This article may not be that much related to supply chain risk, but it is not totally unrelated.

Are you the weakest link in your own supply chain? That’s the question asked in an article in the Harvard Business Review some time ago. The article is geared towards company CEOs, advising them not to get too detached from supply management, but rather to actively engage in their company’s supply chain management, particularly in businesses like manufacturing, retail and distribution. This article may not be that much related to supply chain risk, but it is not totally unrelated.

Seven key areas

The article divides the supply chain domain into seven key areas where CEOs can exert a positive, or conversely, a negative influence:

Picking the right leaders – A CEO should never appoint a person without the appropriate background for a senior position in supply chain management. Even if lateral job rotation is part of management training and the designated career path towards senior management positions, make sure that the supply chain management function is headed by someone who knows supply chain management.

Only a CEO who is up to date on supply-chain practices and trends can properly evaluate a supply-chain executive’s performance.

Initiating benchmarking and devising metrics – A CEO ought to specify goals for improvement of inventory, transportation, and warehousing. In order to do so he need to know benchmarking techniques and best practice metrics.

Ensure that any tool purporting to evaluate customer service assesses the company’s performance from the customer’s viewpoint.

Setting incentives for supportive behavior – A CEO ought to establish reward and incentive programmes to encourage employees to behave in ways that benefit the overall firm, not just their own functions.

Purchasing, logistics, and merchandising managers work in cross-functional teams and are measured — and rewarded — according to supply-chain metrics that assess purchasing costs, logistics costs of getting the product to the store, and the selling price in the store.

Keeping up with supply chain technologies and trends – A CEO should take the time to understand the sophisticated technologies that exist with supply chain management, among which RFID, machine readable codes and bar codes.

A CEO who understands new technologies can play the important devil’s advocate role by challenging the business case for technology adoption.

Eliminating cross-functional crossed wires – A CEO should be aware of and avoid cross-functional sinkholes, where either part of the team has no understanding of the others’ role and function in the overall supply chain.

The CEO should thoroughly understand — so that he can help to harmonise — the interplay of cross-functional and supply chain priorities.

Adding supply chain insight to business planning – A CEO ought to make sure that no key information is missing from the planning stage. Supply-chain considerations should be core components of business planning, including sales and marketing promotions and of contract negotiations with customers and partners, because unforeseen disjunctions can undermine the best strategic intentions.

CEOs, if fully engaged, demand relevant business planning and negotiations anticipate and explicitly address important supply chain ramifications.

Resisting the tyranny of short-term thinking – A CEO should guard, in particular, against allowing quarterly pressures to dictate unprofitable long-term trends. Why? Because it results in

extreme costs and supply disruptions created by a quarterly cycle consisting of overcapacity and inventory build-up for two months, followed by rush production and delivery in the third month

Seven questions

These are the seven question a CEO should ask:

- Is supply chain leadership a valued career path in your company?

- Do you have a program of customer-focused metrics and best-practice benchmarking that drives cross-functional alignment?

- Do employee and customer behavior reflect your supply chain strategies?

- Do you understand important supply chain technology trends?

- Do you play a constructive role in resolving cross-functional disjunctions?

- Do you demand that supply chain expertise be factored into all or most business operations?

- Do you ensure that short-term thinking doesn’t sabotage supply chain strategies?

A scorecard for self assessment

The answer to the seven questions can be assesed using a scorecard:

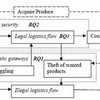

(Click image for larger version)

Conclusion

Although this article is more about suply chain management than supply chain risk, no supply chain is stronger than its weakest link, and weak links are a risk that can and should be avoided. This article is a step towards eliminating these weak links, at least the internal links.

Links

- Harvard Business Review: Are you the weakest link in your company’s supply chain?

Author links

- linkedin.com: Reuben E Slone

- wikipedia.org: John T Mentzer

- linked.com: J Paul Dittmann

Related

- husdal.com: Barcodes – essential to supply chain management?