Following up my previous post, Sparse transportation networks – a recipe for supply chain disruptions?, when it comes to a business’ physical location in relation to the functioning of the supply chain, obviously there are good locations and bad locations. Can a business’ organization compensate for that? Yes – by either structuring its supply chain or honing its organization, thus going from badly located to well located and from badly prepared to well prepared.

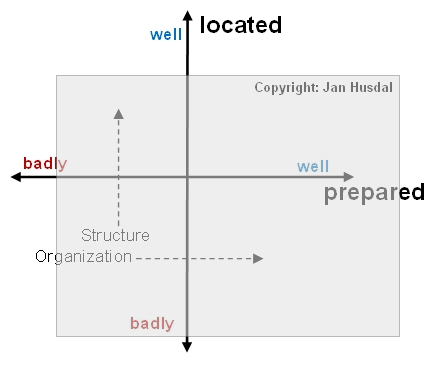

Following up my previous post, Sparse transportation networks – a recipe for supply chain disruptions?, when it comes to a business’ physical location in relation to the functioning of the supply chain, obviously there are good locations and bad locations. Can a business’ organization compensate for that? Yes – by either structuring its supply chain or honing its organization, thus going from badly located to well located and from badly prepared to well prepared.

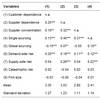

Design Characteristics and Mitigation Capabilities

In The Severity of Supply Chain Disruptions: Design Characteristics and Mitigation Capabilities, Craighead et al. contend that the severity of supply chain disruptions are linked to a) the supply chain design characteristics and b) the supply chain mitigation capabilities. I like to look at it this way: the impact of supply chains disruptions depend on a) the structure and b) the organization of the supply chain, where the structure makes up the physical side (a) of the supply chain and the organization makes up the human side (b) of the supply chain. These two parts are complementary in that both are needed for the successful handling of a supply chain disruption, while at the same time, a deficiency in one part can be compensated by the strength of the other part, i.e. a badly structured supply chain can be strengthened by a well organized supply chain. How?

Resilient organizations

In the New Zealand research project Resilient Organisations the focus is NOT on the vulnerability of systems to failure, but on the ability to manage and minimize the impact of any failures. This is achieved by focusing on organizational preparedness.

If the supply chain structure represents a company’s location and the supply chain mitigation capabilities or organization represent a company’s preparedness, ideally then, a company will be both well-located and well-prepared vis-à-vis any form of disruption. Conversely, given a supply chain structure prone to disruption, combined with a lack of organization, a company will be both badly located and badly prepared. This implies that firms placed in disadvantageous locations can notably better their supply chain by focusing on improving their supply chain characteristics.

Location versus preparation

In regions or countries with sparse transportation networks or few transportation mode choices the structure or design of the supply chain becomes an important factor in determining if a company has an advantageous or a disadvantageous location.

By re-designing the structure, locational disadvantages can be lessened or entirely eliminated, and a supply chain wise “badly” located company can become “well” located. Conversely, if the structure cannot be improved (or not be improved further), by re-designing the organization, proper training and adding supply chain visibility such that early warnings and early proactive and reactive actions are possible, a company can turn from badly prepared into well prepared.