Supply chain management used to be relegated to the logistics department of businesses and hardly thought of as matters concerning the top-level management. Similarly, risk management was handled by insurance specialists who concentrated on facilities, employees and shipping losses and security. However, in my opinion, risk and particularly supply chain risk should be an integral part of any board room discussion. Why?

Supply chain management used to be relegated to the logistics department of businesses and hardly thought of as matters concerning the top-level management. Similarly, risk management was handled by insurance specialists who concentrated on facilities, employees and shipping losses and security. However, in my opinion, risk and particularly supply chain risk should be an integral part of any board room discussion. Why?

Supply Chain Risk Management = Business Continuity Management

As companies now source their materials from sources further and further away, and as key customers are increasingly spread around the globe, the logistics chains have grown more and more complex, while leading to lesser and lesser control over the supply chain, and hence, lesser control over potential disruption causes. Consequently, companies may be left with control “only” over possible disruption impacts and consequences.

The now classic textbook example of Nokia and Ericsson in 2000 shows how a well-handled disruption can translate into business continuity, while an ill-handled supply chain disruption soon can turn into business dis-continuity.

Even a small, localized event far away can have consequences not only for the business directly involved, but potentially across the global economic system. That’s why supply chain risk never should be overlooked or left to the experts alone.

Risks and uncertainty in supply chains

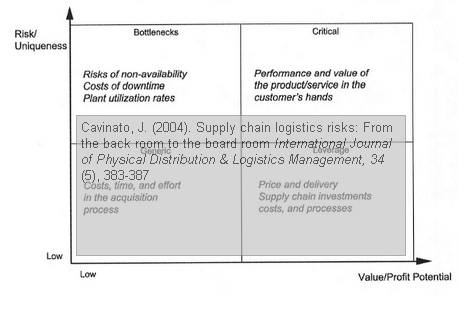

In his 2004 paper, Joseph L. Cavinato points out five sub-networs within the supply chain that need special attention:

- Physical – the actual movement of goods, shipping and warehousing

- Financial – the flow of cash, income and expenses

- Informational – electronic systems, data capture, processing and sharing

- Relational – customer and supplier relationships

- Innovational – the discovery and application of new producs, services and processes

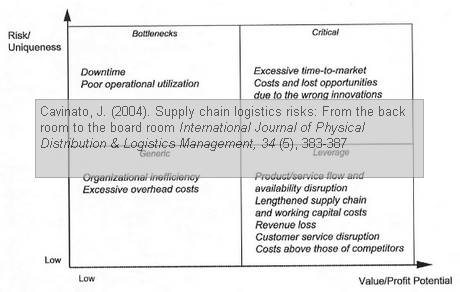

The sub-chains are the related to the Krajjic 1983 model, showing that there is a connection between value/profit potential and risk, and distinct differences as to which should be the areas of concern depending on risk and profit potential.

Supply chain governance

In conclusion Cavinato coins the term supply chain governance, indicating that governance models should be applied throughout the entire supply chain, ranging from the fourth-tier or further-tier suppliers through to the ultimate consumers and customers. Cavinato contends, and I fully agress with him on this, that taking risk and uncertainty into the supply chain will most certainly broaden the initially narrow and marginal field of logistics and turn it into a hotbed for boardroom discussions.

References

Cavinato, J. (2004). Supply chain logistics risks: From the back room to the board room International Journal of Physical Distribution & Logistics Management, 34 (5), 383-387 DOI: 10.1108/09600030410545427

Krajlic, P. (1983) Purchasing must become supply management. Harvard Business Review, Vol. 61, No. 5, pp. 109-117.