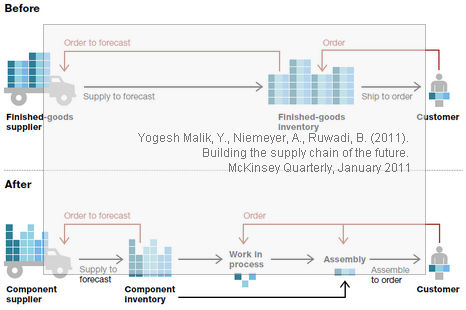

Many global supply chains are not equipped to cope with the world we are entering. Most were engineered, some brilliantly, to manage stable, high-volume production in China and other low-cost countries. But in a future when the relative attractiveness of manufacturing locations changes quickly—along with the ability to produce large volumes economically— such standard approaches can leave companies dangerously exposed. So say Yogesh Malik, Alex Niemeyer, and Brian Ruwadi in the McKinsey Quarterly of January 2011. Essentially, in the future, economies of scale need to be replaced by economies of flexibility in order to cope with the risks of turbulent and shifting sourcing and manufacturing opportunities, wherever they occur…and disappear again.

Many global supply chains are not equipped to cope with the world we are entering. Most were engineered, some brilliantly, to manage stable, high-volume production in China and other low-cost countries. But in a future when the relative attractiveness of manufacturing locations changes quickly—along with the ability to produce large volumes economically— such standard approaches can leave companies dangerously exposed. So say Yogesh Malik, Alex Niemeyer, and Brian Ruwadi in the McKinsey Quarterly of January 2011. Essentially, in the future, economies of scale need to be replaced by economies of flexibility in order to cope with the risks of turbulent and shifting sourcing and manufacturing opportunities, wherever they occur…and disappear again.

Avoiding turbulence

In a way, this post is is following up my previous post on supply chain turbulence, where supply chains were exposed to external volatility and uncertainty. However, following McKinsey this uncertainty can also be an advantage, if the flexibility in sourcing and production is turned into something positive, because while globalization obviously brings complexities into the supply chain, the rising incomes in developing countries make them extremely desirable as markets, not just manufacturing hubs:

Economic growth in the emerging markets will boost global energy consumption in the coming decade by about one-third. Meanwhile, the voracious appetite of China and other developing countries for such resources as iron ore and agricultural commodities is boosting global prices and making it trickier to configure supply chain assets.

Interestingly, the report makes this bold statement: “In such a world, the idea that companies can optimize their supply chains once—and for all circumstances and customers—is a fantasy.” The remedy, so the report goes on to suggest, is to view the supply chain as dynamic hedge against uncertainty by actively and regularly examining—even reconfiguring—the broader supply network with an eye toward economic conditions five or ten years ahead. Another remedy is to splinter the traditional monolithic supply chain into smaller and more flexible units.

The report explains how the ability of supply chains to withstand a variety of different scenarios influences the profitability and even the viability of organizations in the not-too-distant future. In light of this, so the report says, companies should design their portfolios of manufacturing and supplier networks to minimize the total cost risk under different scenarios. The goal should be identifying a resilient manufacturing and sourcing footprint—even when it’s not necessarily the lowest cost one today. The idea is that future flexibility will pay off in the long run.

Reference

Malik, Y., Niemeyer, A., Ruwadi, B. (2011). Building the supply chain of the future. McKinsey Quarterly, January 2011.

Author links

- linkedin.com: Yogesh Malik

- linkedin.com: Alex Niemeyer

- unknown: Brian Ruwadi

Related posts

- husdal.com: The IBM supply chain of the future

- husdal.com: Supply Chain Turbulence